10

/

14

5. Laser GRBL software

Laser GRBL is an excellent and practical opening source controls software in the field of laser engraving. Compared

with similar software, it has a simple interface, simple operation, and supports multiple languages. There are a lot of

learning resources used on the Internet, which is convenient for beginners to understand and master the software.

Mastering a laser engraving software is the basic condition for using laser engraving machine. It is recommended that

beginners first learn the operation method of the software online before using it to prevent damage to the laser

engraving machine and surrounding items by improper operation.

5.1 Download and installation

Download from Laser GRBL official website or ask our customer service to get the archive contains two files:

(1) CH340 USB driver Unzip the package and find the file

DRVSETUP64.exe

. Double-click to install, the user needs to

install this driver when running the software for the first time.

(2) Laser GRBL software locate the file (install.exe) in the archive, double-click it to install it.

5.2

Online operation steps

Online operation is the operation of controlling the device through software after the device is connected to the

computer.

(1). Connect the device to the computer with a USB cable.

(2). Place the material to be engraved in the working area of the engraving machine. Turn on the weak light, focus by

rotating the laser focus knob until the spot becomes smallest and clearest, then the focus is complete.

(3) Open the Laser GRBL software, select the COM port (except COM1, you can plug and unplug the USB cable to see

which one is) and the baud rate (generally set to 115200), then click the connection, the color of the button will become

darker after the connection is successful (if Click the connect button and the color does not become darker. You can

unplug the USB cable and plug it in again.)

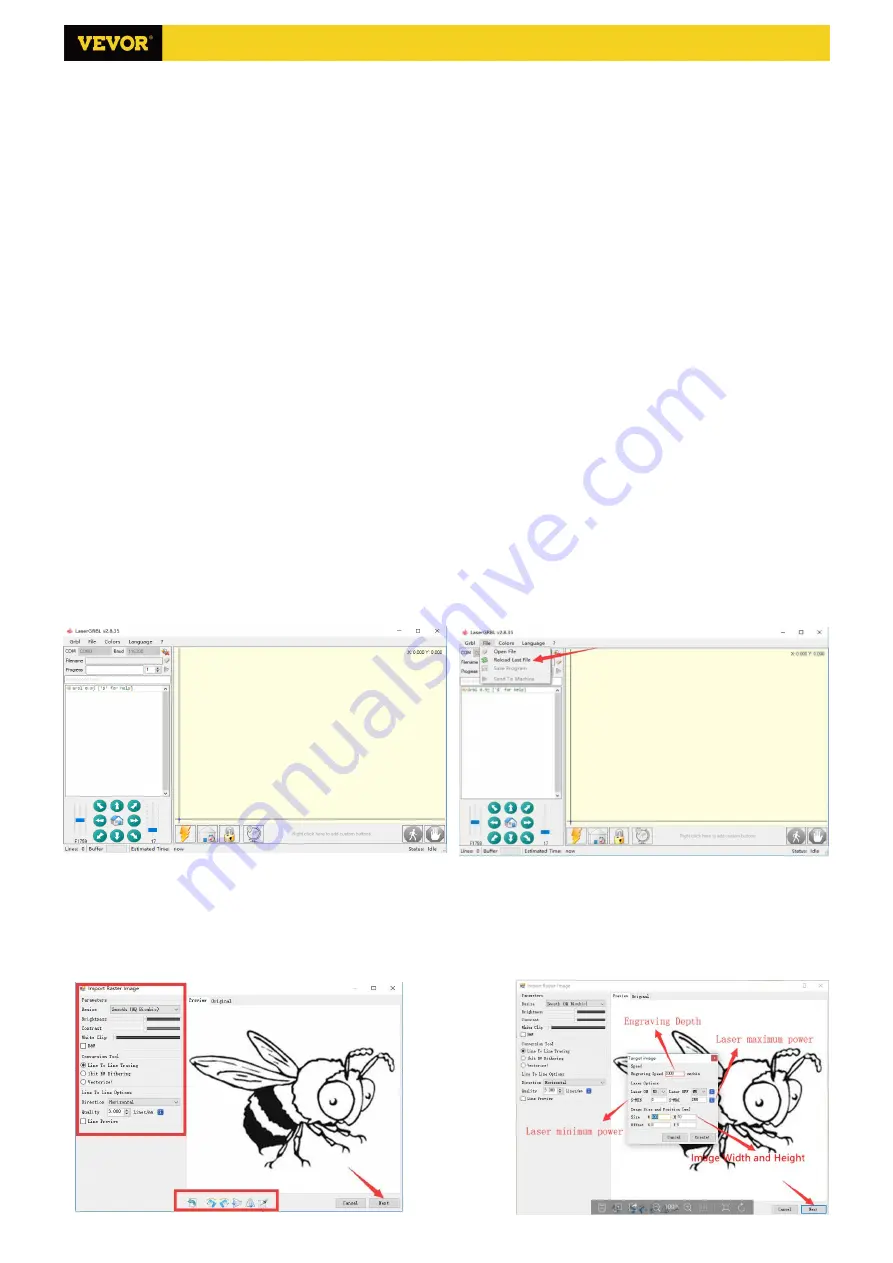

(4).

Af er he connec ion is s ccessf l, click File on he men bar of he in erface o en er he selec ion file in erface,

selec Open File , impor he pic re o be

engraved, etc.

(5).

Selec he file o be engra ed, click Open , he

Inp Ras er Image

dialog box will pop up. Here is the setting engraving mode and some other engraving

parame ers. Click Ne

af er se ing.

(6).

Click Ne

o pop p he Targe Image dialog bo , here o can se he engra ing speed, minim m po er

and maximum

po er and he leng h and id h of he image o be engra ed and offse . Click Crea e af er se ing.

S3018 Pro Ver 2.3