WARNING!

Risk of injury from incorrectly executed work on the ManuTel

®

G2!

The carrying capacity of the Manu

Tel

®

G2 ultimately depends on its

material characteristics. Unauthorised modification such as boreholes for

add-ons, welding work etc. could compromise the carrying capacity and

result in serious accidents from falling loads.

–

Never make any independent modifications (e.g. boreholes, welding)

to the Manu

Tel

®

G2.

–

Adhere to the prescribed maintenance intervals.

WARNING!

Risk of injury from tipping or slipping load!

Incorrect lifting of loads could cause the load to tip or slip and cause

serious injuries.

–

Space the fork arms equally from the middle of the vehicle and lock

them in position.

–

Take hold of the load with the Manu

Tel

®

G2 as far from its centre as

possible.

–

Raise the load using its entire length and distribute it evenly on both

Manu

Tel

®

G2s.

WARNING!

Danger due to slipping load!

If there is moisture, dirt or ice on the lifting surfaces of the Manu

Tel

®

G2,

there is an increased risk of the load slipping. A slipping load could cause

serious injuries.

–

Remove any dirt from the Manu

Tel

®

G2 before lifting the load.

–

In wet, snowy or icy conditions etc., secure the load with e.g. tension

belts.

WARNING!

Risk of injury from missing locking device!

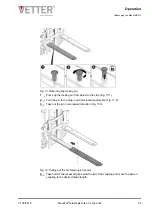

The locking device prevents undesired lateral movement of the Manu

Tel

®

G2 on the profile of the fork carriage. Uncontrolled movement of the

Manu

Tel

®

G2 during transportation could cause the load to slip and

cause serious injuries!

–

Safeguard the function of the locking device.

–

Replace damaged locking devices immediately.

–

If the locking device is missing, it must be replaced before start-up.

Unauthorised

modification

Incorrect fork

arm spacing

Moisture and

dirt

Checking the

locking device

Safety

Dangers associated with handling the ManuTel® G2

V1.09/2019

ManuTel

®

telescopic fork arm Type G2

11