Rev. 9/25/2017

HDC-450, MANUAL

Copyright 2017 Vestil Manufacturing Corp. Page 12 of 26

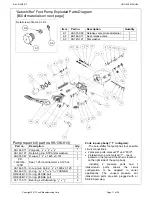

Autoshifter Foot Pump Bill of Materials:

Hydraulic System Inspections and Maintenance:

Before putting this drum carrier into service, create a written record of the appearance and operation of the foot

pump, cylinder, and hydraulic hoses. Use the foot pump to extend the cylinder and then retract it by pressing the

release lever. Include details in your record about the amount of effort necessary to move the foot pedal as well as

how the pump and cylinder look and sound during extension and retraction. This record establishes normal condition

of the pump and cylinder. During subsequent inspections, compare observations to the written record to determine

whether the pump and cylinder are in normal condition.

Unload the drum carriage and lower the pivot arm before inspecting the pump or performing maintenance on it.

(A) Before Each Use Check For Any of the Following Conditions. Do not return the unit to service unless it is in normal

operating condition.

Oil leaks from the pump, hoses, hose fittings, etc.

Pinched or chafed hoses

Item no.

Part No.

Description

Quantity

1

99-039-001

Body, manual pump, 1.75/0.75 bore

1

2

99-041-001 Piston,

pump,

1

1

/

4

” x

3

/

4

” 1

3

99-041-002 Piston,

pump,

unloader

1

4

99-110-007 Bearing,

ball,

1

/

4

” 3

5

99-110-006 Bearing,

ball,

3

/

8

” 3

6

99-153-038

Flow control, pressure compensated, 1.0 gal.

1

7

99-114-001

Washer, beveled spring washer

8

8

99-146-008 Spring,

relief

1

9

99-653-005

Assembly, release valve packing

1

9.1

99-031-022

Accessory, hydraulic, relief valve pin seal retainer

1

9.2

99-144-017

Seal, release valve

1

9.3

99-145-127 Washer,

star

1

10

99-031-066

Plug, SAE #6 port

3

11

99-112-009

Pin, release pin

1

12

99-016-018

Bracket, pivot plate

1

13

01-111-013 Bushing,

polygon

1

/

2

” inner diameter x

1

/

2

” long

2

14 99-112-008

Pin,

pivot

1

15

20-110-003

Cam roller with seal

1

16

99-031-067 Wiper,

1

1

/

4

” inner diameter x 1

1

/

2

” outer diameter x

3

/

16

” 1

17 99-144-018

Seal,

1

1

/

4

” x

1

/

8

” CS

1

18

99-031-068 U-cup,

3

/

4

” outer diameter x

1

/

8

” CS

1

19

25547

Socket head set screw, black oxide finish,

3

/

8

” – 16 x 2”

2

20

25537

SSS, CP, utility grade,

3

/

8

” – 16 x

3

/

8

” 2

21

99-040-001

Lever, release pedal

1

22

64133

Pin, spring pin,

3

/

16

” – 1” long

1

23

99-016-017

Bracket, pedal link

1

24

99-040-002

Lever, foot pedal, 2-speed, auto-shifter

1

25

99-116-005

Morb hollow hex plug, SAE 4

2

26

99-146-004

Spring, compression, inlet check

2

27

99-146-006

Spring, compression, retainer

2

28

99-146-005

Spring, compression, outlet check

2

29

99-146-009

Spring, compression, return piston

1

30

99-146-007 Spring,

release

ball

1

31

99-112-049 Pin,

detent

ring

1

32

36106

Hex nut, grade A, zinc plated,

3

/

8

” – 16

2

33

99-144-019 O-ring,

7

/

32

” inner diameter x

11

/

32

” outer diameter x

1

/

16

” CS

1

34

99-112-050

Pin, spring guide

1

35 99-153-070

Valve,

relief

1

36

99-031-069

Cap, #6 JIC

1

37

11105

Hex bolt, grade A, zinc plated,

3

/

8

” – 16 x 1”

1

38

33622

Split lock washer, carbon steel, medium zinc finish,

3

/

8

” 3