5

INSTALLATION OF EDGE-O-DOCK

PE AND PP SERIES

Installation of PP Series

1.

Install the PP leveler and bumpers per the preceding instructions.

2.

Install the cylinder with the supplied parts (rod end up) at bottom only. Keep the cylinder closed (piston retracted).

3.

Mount the hand pump adjacent to the leveler on a post or wall. Drill a hole thru the wall for hydraulic hose.

4.

Attach the hydraulic line to the pump, run to the cylinder and loosely attach to the cylinder.

5.

Fill the pump reservoir with the oil. Pump oil into line. Continue pumping slowly until air ceases to escape from cylinder.

6.

Tighten fitting on cylinder and continue pumping until cylinder extends enough to attach to top bracket. Attach cylinder.

Installation of PE Series

1.

Install the PE leveler and bumpers per preceding instructions.

2.

Install the cylinder with the supplied parts (rod end up).

3.

Remove the shipping plug in the reservoir and install the breather vent.

4.

Mount the control box on the inside wall of the building at a convenient height. Drill a hole through the wall for 1/2"

conduit. Run the conduit from the hydraulic pump motor, below the bumper, and up through the hole previously drilled.

5.

Follow standard electrical procedures and all applicable codes when installing the control box to the hydraulic unit

(See electrical the schematic on page 6).

6.

Check the operation of the leveler. Push the

RAISE

button and hold it in until the cylinder is fully extended. Release the

button and the leveler should descend to a work position. If the leveler fails to operate, check the electrical connections

to verify proper connections, power source on, and fuses installed and functioning. Operate at least 6 full cycles.

7.

Grease all hinge fittings at the time of installation and every 3 months thereafter.

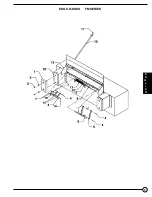

PE Series

Control Box

Hydraulic Cylinder

Hydraulic Hose

Hydraulic Power Unit

(Fill with AW-32 hydraulic oil)

Grease Fittings

E

N

G

L

I

S

H