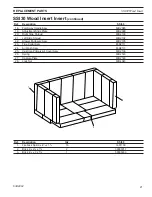

SSI30 Wood Insert

63D4004

19

ST1088

replace baffle

ST1088

Figure 27 -

Replace Baffle

MAINTENANCE

far enough forward so the chimney brush will not damage

it when cleaning.

Figure 26.

There is no need to remove

the secondary air tubes for cleaning.

frayed or worn, replace immediately. Contact your dealer

for approved replacement parts. Refer to replacement parts

list in this manual.

NOTE:

Wear safety glasses and gloves when performing

any maintenance task.

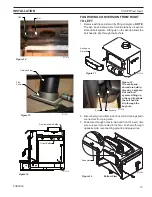

The following steps should be followed for glass gasket

replacement:

1. Ensure appliance is not in operation and is thoroughly

cooled

2. Remove door and place on a protected flat surface.

3. Remove screws and glass clips.

4. Lift glass out.

5. Remove old gasket and clean or replace glass.

6. Sand gasket groove and wipe clean (rubbing alcohol

works well).

7. Put a thin film of gasket cement on the door.

8. Replace new gasket starting at the top center of the

door.

9. Trim to length and butt ends together. Remove all

excess cement.

10.Replace glass in door, being sure not to over-tighten

screws and clips.

dOOR gASkET REplACEMENT

The following steps should be followed for door gasket

replacement:

1. Ensure appliance is not in operation and is thoroughly

cooled.

2. Remove door and place on a protected flat surface.

3. Remove old door gasket and clean channel.

4. Sand gasket groove and wipe clean (rubbing alcohol

works well).

5. Using an approved high temperature gasket cement,

apply a thin coat in bottom of channel.

6. Starting at top center of door, work into channel around

door unit, trim to length and butt ends.

7. Close door and allow three to four hours for cement to

set before restarting appliance.

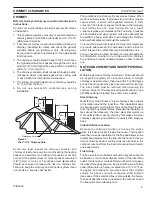

ASh dISpOSAl

Ashes should be placed in a metal container with a tight-

fitting lid. The closed container of ashes should be placed

on a non-combustible floor or on the ground, well away

from all combustible materials, pending final disposal. If the

ashes are disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed container

until all cinders have thoroughly cooled. Other waste should

not be placed in the ash container.

W

ARNING

ThINgS TO REMEMbER IN CASE OF

ChIMNEY FIRE:

1. ClOSE dRAFT CONTROl

2. CAll ThE FIRE dEpARTMENT

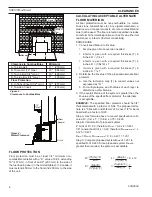

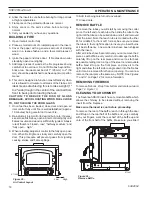

After the chimney has been cleaned clean out the firebox

and carefully replace the rear half of the baffle. Check to

see that both pieces of the baffle are down on the steel

baffle and pushed all the way to the rear of the firebox.

Figure 27

REplACE glASS ONlY WITh hIgh TEMpERATuRE

CERAMIC AvA/IlAblE FROM YOuR lOCAl vERMONT

CASTINgS dEAlER

Use of glass or other components from alternative sources

may cause a safety hazard and may void your warranty.

The following use and safety tips should be observed:

1. Inspect the glass regularly for cracks and breaks. If you

detect a crack or break, extinguish the fire immediately,

and contact your dealer for replacement.

2. Do not slam door or otherwise impact the glass. When

closing doors, make sure that logs or other objects do

not protrude to impact the glass.

3. Do not clean the glass with materials which may scratch

(or otherwise damage) the glass. Scratches on the

glass can develop into cracks or breaks.

4. Never attempt to clean the glass while unit is hot. Light

deposits are normal. Heavier deposits may be removed

with the use of a readily available oven cleaner.

5. Never put substances which can ignite explosively in

the unit since even small explosions in confined areas

can blow out the glass.

6. This unit has an air wash system designed to reduce

deposits on glass.

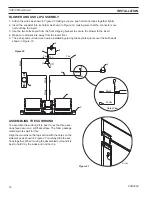

gASkET REplACEMENT

After extensive use, the gasket material which provides

glass and door seal may need to be replaced if it fails

to sustain its resilience. Inspect glass and door seal

periodically to ensure proper seal: if gaskets become