1

1

/

4

"

2

1

/

8

"

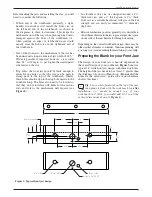

Figure 11: Mounting screw hole depth.

Install the #14 fl at-head screws to secure the front plate

to the front jaw.

#14 × 2

"

Flat-Head

Wood Screws

Figure 12: Attaching front plate to front jaw.

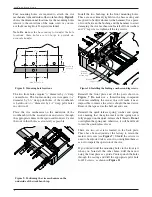

Remove the clamps holding the jaw to the apron. Flip

the workbench upright (or reinstall the workbench

top on its base). Insert the handle into the tee, slide

an O-ring onto each end of the handle, then attach the

end caps with the #8 screws, as shown in

Figure 13

.

(The O-rings will protect the end caps from banging

into the tee as the handle is rotated.)

#8 × 1

1

/

2

"

Flat-Head

Wood Screw

Handle

End Cap

O-Ring

Handle

Figure 13: Installing the handle.

Plane the top of the jaw so that it is fl ush with the top

of the workbench. Apply the desired fi nish to the jaw.

Use

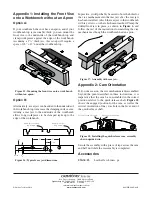

A novel feature of this vise is the quick-release half nut.

To actuate, fl ip the quick-release lever from horizontal

to vertical, as shown in

Figure 14

. (You may need to

rotate the handle to release the threads.)

Cam lever in engaged position.

Rotate cam lever to "up" position

to release main screw.

Figure 14: Releasing the half nut.

Caution: Do not

release the half nut when the vise

is loaded. Disengaging a loaded vise will result in

sudden release of clamping pressure, which can lead to

damage of the vise and workpiece, as well as injury to

the user.

To re-engage the half nut, simply fl ip the lever back to

horizontal. If the threads in the half nut are not aligned

with those on the main screw, the lever may not return

immediately to horizontal. If this is the case, you can align

the threads by rotating the main screw; this will, in turn,

force the quick-release spring to nudge the half nut into

place, and snap the quick-release lever to horizontal.

Care and Maintenance

The vise comes fully lubricated; however, it will need

periodic cleaning and lubrication. White grease on the

main screw will ensure smooth operation, and a light

oiling of the half nut will keep this component moving

freely. The guide rods do not require lubrication; they

have a surface treatment that is self-lubricating and

prevents rust.

Note:

Do not

use silicone-based lubricants on the

main screw. The main screw has a special hardening

treatment and surface coating that is not compatible

with silicone-based lubricants.

7

Veritas

®

Quick-Release Front Vise