080107.02

3

vetus®

Extractor fan type TWinlineA / TWinlineB / TWinlineC / TWinlineD

ENGLISH

1 Introduction

The VETUS extractor fan type TWinlineA / TWinlineB / TWinlineC / TWin-

lineD is intended for ventilating the engine room, toilet or kitchen.

W

arning

In order to prevent personal injury, the electrical supply should always be

disconnected during installation and maintenance.

Never use the fan where the ambient temperature exceeds 70º C (158

degrees F).

c

aution

We

DO NOT

recommend that this extractor fan is used to supply air to

the ship’s engine. Any engine will be able to supply itself with air, provid-

ed the ventilation openings in the engine room are large enough. When

a fan is fitted in the engine’s air supply duct, the suction of the engine

intake will make the fan run too fast, causing it to overheat.

2 Operating Instructions

The fan should be switched on for a minimum of 4 minutes and the en-

gine room checked for vapour before the engine is started.

W

arning

NEVER switch the fan on while refuelling.

3 Installation recommendations

The fan can be fitted in a number of different situations.

3.1 Example 1

Here, the ship’s engine does NOT obtain its inlet air separately. The engine

room can only be ventilated by the fan when the engine is stopped. See

Drawing 1.

3.2 Example 2

In this situation, the ship’s engine gets its inlet air separately (via a grille

with plenum chamber). The fan is then used to extract hot air from the

engine room. this can be done while the engine is running or stopped.

See Drawing 2.

3.3 Note

Always ensure that the ventilation openings are large enough, and that

the fan(s) has sufficient capacity. Improperly positioned ventilation open-

ings and insufficient capacity fans can lead to poor functioning of the

ship’s engine. Always read the engine supplier’s installation instructions.

With a

DIESEL engine

, the air should preferably enter the engine room

low down, and be extracted as high up as possible.

With a

PETROL engine

, the air should enter from high up in the engine

room, and be

extracted as low down as possible

, where it is most like-

ly that vapour will collect. This point should always be below the top of

the engine foundation. However, the duct opening should not be so low

that there is a risk of bilge water being sucked into the fan.

4 Installation

Fit the fan in a bulkhead or floor, high enough above the bilge water level,

in a place free from splashes, drips or deck swabbing water. The ventilator

should be fitted facing downwards, to allow natural water drainage. This

will prevent water collecting in the fan.

Determine the position of the fitting holes. Use the fan as a guide. Drill

holes for 4.8 mm. (no. 10) screws. Fix the fan with the screws. Tighten up

the screws evenly.

4.1 Ventilation Duct

Fit ventilation ducting which conforms to the following requirements:

- Smooth inside

- Resistant to a temperature of at least 70º C (158 degrees F)

- Resistant to water, oil and fuel

- Resistant to under and over-pressure

with an internal diameter of: TWinlineA / TWinlineC : 76 mm (3”)

TWinlineB / TWinlineD: 102 mm (4")

Keep the ventilation ducting as short as possible with as few bends as

possible. Keep the radius of any bends as large as possible.

Fit the duct with a screwing movement to the duct outlet. Fix ducting

with stainless steel hose clamps. A ridge on the duct connectors keeps

the ducting in place and ensures that they will not slide off after instal-

lation.

W

arning

Fit a grille over the extractor opening when the fan does not have a venti-

lation duct. This will prevent touching the revolving fan blades.

4.2 Electrical Connections

Check that the ship’s voltage is the same as the voltage stated on the

fan (12 or 24 Volt).

Connect ‘+’ and ‘-’ as shown in the diagram, see drawing 3. A main switch*

and a fuse** must be incorporated in the positive cable.

*) The switch must be rated for 10 Amps.

**) Consult the diagram for the correct value of the fuse.

Extend the connector wires if required. The minimum core wire cross-

section is 1.5 mm

2

, the insulation must be resistant to more than 70 de-

grees C.

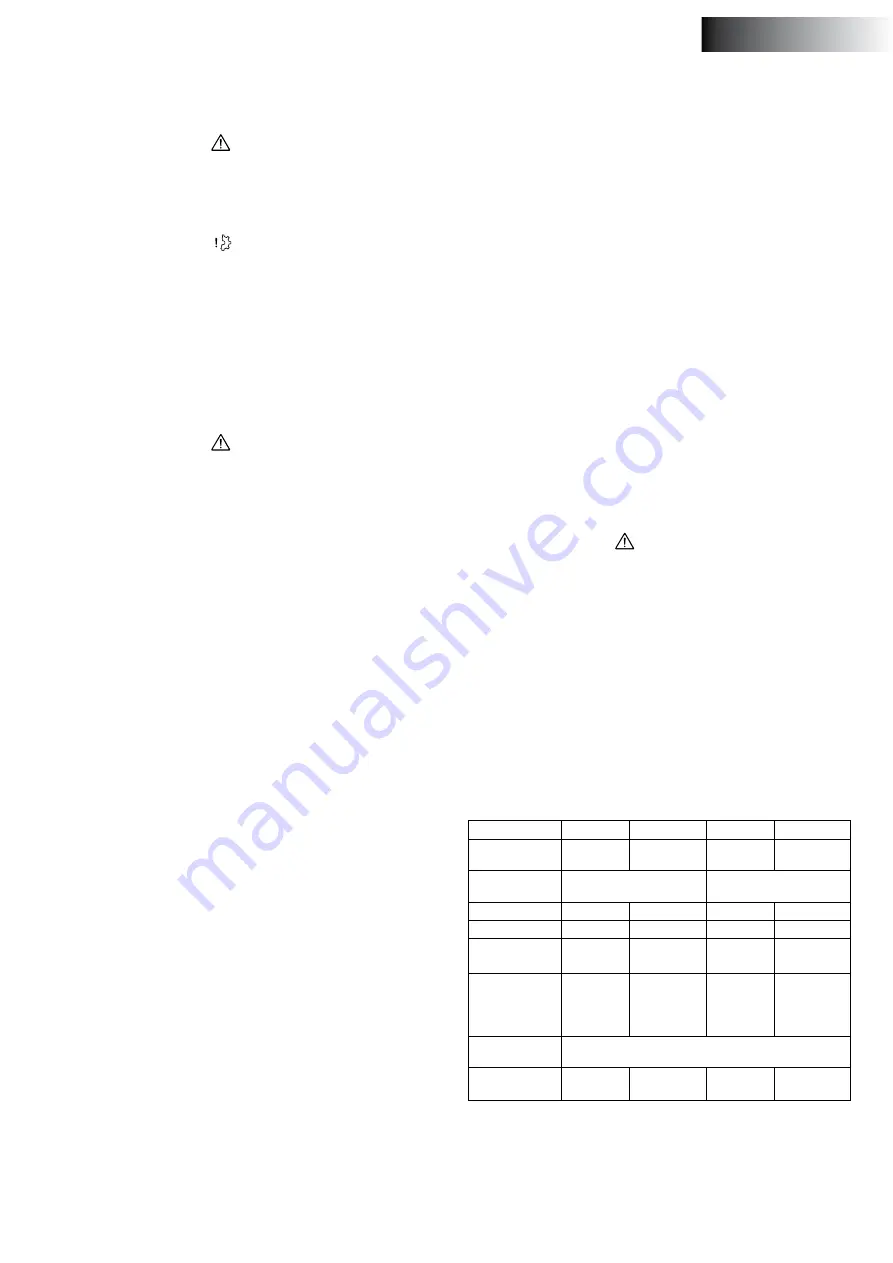

5 Technical Data

TWINLINE

A

B

C

D

Hose connec-

tion:

ø 76 mm

(3”)

ø 102 mm

(4”)

ø 76 mm

(3”)

ø 102 mm

(4”)

Nominal

voltage:

12 V DC

24 V DC

RPM:

9.500

7.500

9.500

7.500

Current *):

2.8 A

8 A

1.6 A

5 A

Capacity, max:

5 m

3

/min

(176 CFM)

7 m

3

/min

(247 CFM)

5 m

3

/min

(176 CFM)

7 m

3

/min

(247 CFM)

Static Pressure,

max:

25 mm (1")

H

2

O at

2,5 m

3

/min

(88 CFM)

45 mm (1

3

/

4

")

H

2

O at

1,4 m

3

/min

(49 CFM)

25 mm (1")

H

2

O at

2,5 m

3

/min

(88 CFM)

45 mm

(1

3

/

4

") H

2

O at

1,4 m

3

/min

(49 CFM)

Ambient tem-

perature:

maximum 70 degrees C (158 degrees F)

Weight:

0.4 kg

(0.9 lbs)

0.5 kg

(1.1 lbs)

0.4 kg

(0.9 lbs)

0.5 kg

(1.1 lbs)

*) Current at resp. 12.6 V / 25.4 V and with 10 m (33 ft) ventilation duct.

The motor is ‘Ignition protected’.

This fan conforms to the ‘ABYC’ and ‘Coast Guard Safety Standards’.