20

MAINTENANCE

The unit must undergo technical maintenance 3 to 4 times a year. Maintenance includes general cleaning of the unit and the following

operations:

1. Filter maintenance.

Contaminated fi lters increase air resistance thus impairing supply air delivery into the premises. The fi lters should be cleaned as they get

dirty, but at least 3-4 times a year. Vacuum cleaning for the air fi lters is allowed. For new fi lters contact your Seller.

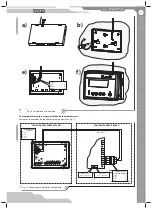

2. Heat exchanger maintenance.

Even regular technical maintenance of the fi lters may not completely prevent dirt accumulation on the heat exchanger casing. Clean the

heat exchanger on a regular basis to ensure high heat recovery effi

ciency. To clean the heat exchanger remove it from the unit and wash with

warm neutral detergent solution. Re-install the dry heat exchanger into the unit.

3. Fan maintenance (once a year).

Even regular technical maintenance may not completely prevent dirt accumulation in the fans which reduces the fan capacity and

impairs supply air delivery into the premises.

Clean the fans with a soft sloth or a brush. Do not use water, aggressive solvents or sharp objects as they may damage the impeller.

4. Condensate drain check (once a year).

The condensate drain (line) may get clogged by dirt and dust particles contained in the exhaust air. Check the drain line operation by

fi lling the drain pan under the unit with water, clean the U-trap and the drain line, if necessary.

5. Fresh air supply duct check (twice a year).

The supply duct grille may get clogged with leaves and other objects reducing the unit performance and supply air delivery. Check the

supply duct grill twice a year and clean it as required.

6. Duct system check (every 5 years).

Even regular fulfi lling of all the prescribed above maintenance operations may not completely prevent dirt accumulation in the air ducts

which reduces the unit capacity. The air duct maintenance includes their periodic cleaning or replacement.

7. Extract shutters and supply diff user cleaning (as required).

Remove the diff users and louvre shutters and wash those with hot soap water. Do not change the mounting position of the diff users

and the shutters.

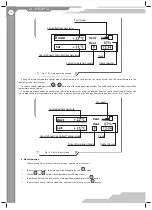

7. Emergency Alarms.

On triggering of either the sensor thermal switch deenergizing the heating elements or in case of fi lter clogging (which triggers the

diff erential pressure sensor) or communication line damage the unit enters the emergency «Electric heating elements blowing» mode with

subsequent shutdown in 2 minutes. The red LED goes on, and the control panel displays the message about the malfunction and its origin.

Fault!!!

Heater overheating

Unit OFF

Fault!!!

Filter clogging

Unit OFF

Fault!!!

No communication

Unit OFF

Summary of Contents for VUT 1000 EH

Page 25: ...V28EN 04 ...