6.

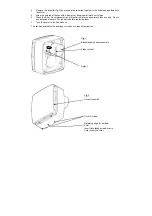

Remove the small Internal Cover that covers the Terminal Block in the top right corner (

fig 3

).

7.

Using the Fan Chassis as a template, carefully sliding the spigot into the Wall Liner, mark the

fixing hole centres on the wall.

8.

Drill and plug the wall using the fixings provided.

9.

Feed the wiring through the hole near the Terminal Block (

fig.

4) and secure the Fan into

position using the screws provided.

10. Select and follow the appropriate wiring diagram in

Section C WIRING.

11. Replace the Internal Cover over the Terminal Block.

12. Ensure the Impeller (

fig.3

) rotates freely.

13. Replace the Front Cover Assembly and tighten the two screws.

14. Switch the mains power supply on and check the fan is operating correctly

FLUSH MOUNTING (PANEL/CEILING)

A Flush Mount Kit (439256) is required.

1.

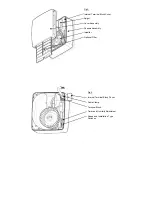

Remove the Front Assembly by slackening 2 Cover Screws by 2 turns (

fig.2).

Lift the front

assembly away from the bottom edge then the top edge.

2.

Mark and cut a rectangular hole 225mm (w) x 255mm (h) through the panel ensuring that

there is sufficient space for the product to be installed and that the optional Filter (

fig.3

) can

be removed for maintenance.

3.

Remove the Back Box by removing the 4 screws. Replace it with the Frame from the

Accessory Kit 439256. (

Fig 5

).

4.

Slide each Panel Clip in to the Chassis then pass each of the long Panel Clip Screws

(supplied in the kit) fully through the flange of the Chassis and screw in to the Panel Clips

(fig.6.)

allowing enough space between the Panel Clip and the flange for the thickness of the

panel (so that the clips can spring open behind the panel).

5.

Set-up the appropriate speed selection and other features as outlined in

Section B SETUP.

6.

Remove the Internal Terminal Block Cover that covers the Terminal Block in the top right

corner (

fig 3 & 4

).

7.

Attach the ducting to the Spigot and locate into the hole in the panel, ensuring the cable is

fed into the Fan Chassis (

fig.

4) and the Panel Clips spring out behind the panel.

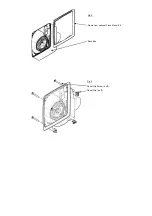

8.

Secure into position by carefully tightening the 4 Panel Clip Screws.

IMPORTANT: If power

tools are used, set them to the minimum torque setting or preferably use a manual

screwdriver. Do not over tighten.

9.

Select and follow the appropriate wiring diagram in

Section C WIRING.

10. Replace the Internal Cover over the Terminal Block.

11. Ensure the Impeller rotates freely (

fig.3

).

12. Replace the Front Cover Assembly and tighten the two screws.

13. Switch the mains power supply on and check the fan is operating correctly.

B. SETUP

WARNING: THE FAN AND ANCILLARY CONTROL EQUIPMENT MUST BE

ISOLATED FROM THE POWER SUPPLY DURING INSTALLATION OR

MAINTENANCE.

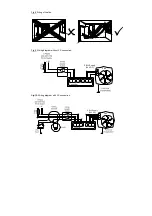

With the Cover removed the humidity adjustment, overrun timer adjustment, speed selection

switches and installation type switches are accessible in the bottom right corner of the product

(

figs.4 & 7

).

1. SELECTING THE CONSTANT TRICKLE SPEED (0, 6, 9 or 12 l/s)

This will determine the speed at which the fan will run most of the time except when boost is

activated by either the Pullcord, PIR, LS, or Relative Humidity Sensor.

i.

Slide one of the three switches marked as ‘Normal/Trickle Speed’ in

fig.7

to the right (on

position) to select that flow rate for trickle speed.