3.0 Installation

8

CE-1-11/00

3.1

Installing the Unit

18. External grilles placed in the soffit should

be positioned at the same distances as

indicated for gables.

19. The Quicktube Rigid UPVC duct system

permits fast, easy assembly whilst ensuring

pressure-proof system sealing.

20. The ducts are delivered in lengths of 3m

and are easily shortened as required with a

duct saw or a similar fine toothed saw. We

recommend that you file the edges of the ducts

after shortening.

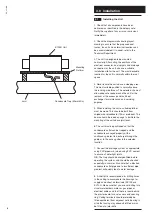

21. Assemble the duct and fittings, following as

closely as possible the diagrammatic ducting

layout. Ensure that the duct is raised above

joist level to allow for thermal insulation of the

ducting.

22. Each straight length of duct is assembled

using a flexible connector (QTC) to join the two

ends, whilst 90° and 45° diversions and

branches are accomplished with flexible fittings

(QTB90, QTB45 and QTET). The duct is a push

fit into the socket of the connector and fittings.

23. Once assembled the joints are secured with

duct tape (DT30) to provide an airtight seal.

Ensure that the tape is secured over the

complete joint area to provide an airtight seal.

24. If the loft space is unheated the unit and

ducting will require to be thermally insulated to

preclude condensation occuring and to

minimise heat loss. This requirement must be

observed in the planning and routing of the

duct system.

25. The insulation recommended is Alreflex 1L1

which comprises 3mm thick polyethylene

bubble sheet laminated on the external surface

with aluminium foil protected by a thin

polythene film. The product is CFC and HFC

free and has a surface spread of flame of Class

1 tested to BS476 Part 7/971. It should,

however, be protected from open flames or

sparks and stored apart from highly flammable

materials.