6.0 Maintenance

12

CE-1-11/00

6.1

Cleaning the Unit

In addition to removing odours, providing fresh

air and recovering heat, this unit extracts

airborne impurities such as dust, dirt and

grease. These gradually build up and detract

from the efficiency and appearance of the unit.

To ensure optimum performance, the unit

should be cleaned every three to six months or

at periods determined by the level of

contamination experienced, and according to

the following procedure.

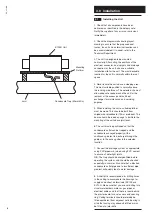

1. Isolate the mains power supply.

2. Remove the four securing screws from either

end of the cover.

3. Remove the cover.

4. Remove the heat exchanger from the unit.

5. Wash the heat exchanger in warm water

using a mild detergent and dry thoroughly.

Keep water away from all electrical components

and wiring within the unit.

If the filter cannot be cleaned, replacement is

recommended.

6. Reassemble in reverse order. The heat

exchanger should be repositioned with the ‘Top’

label facing the front and pointing upwards.

Heat Exchanger

Securing

Screws

Securing Screws

Cover