3.0 Installation

7

CE-1-11/00

3.1

Installing the Unit

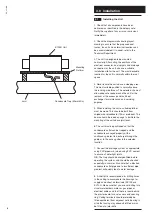

9. Place the terminal housing in the hole in the

ceiling and secure to the back ring with the four

screws provided.

10. For two storey new build properties it is

recommended that the ground floor terminal

housings are secured in position in advance of

the plasterboard panels being fixed, by

obtaining a sheet of plasterboard of the type

and thickness to be used. Cut a square of the

sheet to just span two joists in the corner where

the terminal is to be fitted. Remember that the

edge of the sheet on the inner joist should only

rest on half of the joist thickness. This allows a

fixing surface for the next sheet of plasterboard

to be secured to when it is fitted. Tack up the

plasterboard in position on the ceiling and

connect up and seal the duct and fittings.

11. For two storey existing properties it is

necessary to lift the floor coverings at first floor

level above the terminal positions to gain

access to the terminal housings to secure and

seal the duct and fittings.

12. Fix in position all vertical supply and extract

air ducting being conveyed between ground

floor ceiling level and the loft space.

13. The external grilles for intake and exhaust

air should be positioned so that the exhaust air

is not drawn in again.

14. If the grilles are fitted in the same gable at

the same height, a minimum of 1m between

grilles is recommended.

15. If the grilles are positioned above one

another the distance apart should be at least

1m with the exhaust grille at the top.

16. Roof ventilators placed on the same roof

surface should be positioned at the same

distances as the grilles.

17. Always ensure that all exhaust grilles/roof

ventilators are placed higher than the top edge

of the highest window and at a distance of at

least 1m from the nearest window.

Terminal Housing

Plaster Board

Securing Ring / Back Plate

(for fire valves)

Securing Screw

Terminal