8

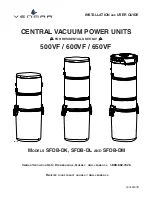

MOUNTING THE POWER UNIT

Carefully remove debris pail from power unit. Make sure bag

is properly installed in power unit (500VF unit only). Remove

the installation kit and securely reinstall debris pail.

Refer to illustration below to maintain minimum walls and

floor clearance dimensions.

Position and install the wall mounting bracket with the

provided screws. Refer to illustration in the right column for

proper mounting dimensions.

Use the provided mounting screws to secure the mounting

bracket on the wall through upper and lower mounting

holes.

Hang power unit onto wall mounting bracket. Ensure

the back brackets of the power unit are engaged with

corresponding wall bracket fingers (or top fingers and lower

tab for 500VF model; see figure below). Pull the power unit

down to secure.

POWER UNIT INSTALLATION (

CONT

'

D

)

C

L

3/4” TYP.

32

7

/

8

”

1” TYP.

45¼”

MIN.

HEIGHT

18 ¹/

8

”

18 ¹/

8

”

UPPER

MOUNTING

HOLES

LOWER

MOUNTING

HOLES

AD0079A

CAUTION

Ensure to screw the wall mounting bracket directly

to a wall stud for a solid installation.

18” minimum

above floor

12” minimum

from ceiling

12”

minimum

TOP VIEW

FRONT VIEW

MINIMUM CLEARANCE DIMENSIONS

12”

minimum

AD0039A

AD0074

600VF AND 650VF

500VF