VEC-1002K Owner's Manual

2 Meter FM Receiver Kit

15

!

!

7. Locate two (2) 10K potentiometers. Install one at R6 (tuning), making

sure the pot is firmly seated before soldering in place.

!

!

8. Install the second 10K pot at R16 (volume), checking seating before

soldering.

!

!

9. Find the 100K pot. Install at R10 (squelch), check seating, and solder.

Phase 9: Coils

!

!

1. Find the .074 uH slug-tuned coil with a red form (144-Coilcraft). This

will be installed at L4. Before installing, make sure the coil's two pins

and two shield-can tabs are straight and aligned with the mounting

holes. Install, and bend the shield-can tabs over to hold the can in

place before soldering.

!

!

2. Find the 660 uH quadrature detector coil (five pins, black coil form).

Make sure all pins and tabs are straight before installing. Install at L5,

bending over the shield-can tabs before soldering in place.

The last three coils in your radio are air-wound types made from the #24 wire

supplied with your kit. In addition to the #24 wire, you'll also need a 6-32 screw

at least 1/2" long to use as a winding form (longer is better).

!

!

3. Carefully straighten the coil wire (drawing it over a plastic rounded

surface such as a screwdriver handle works well). Remove all bends

and kinks. Cut two (2) lengths about 5" long each.

!

!

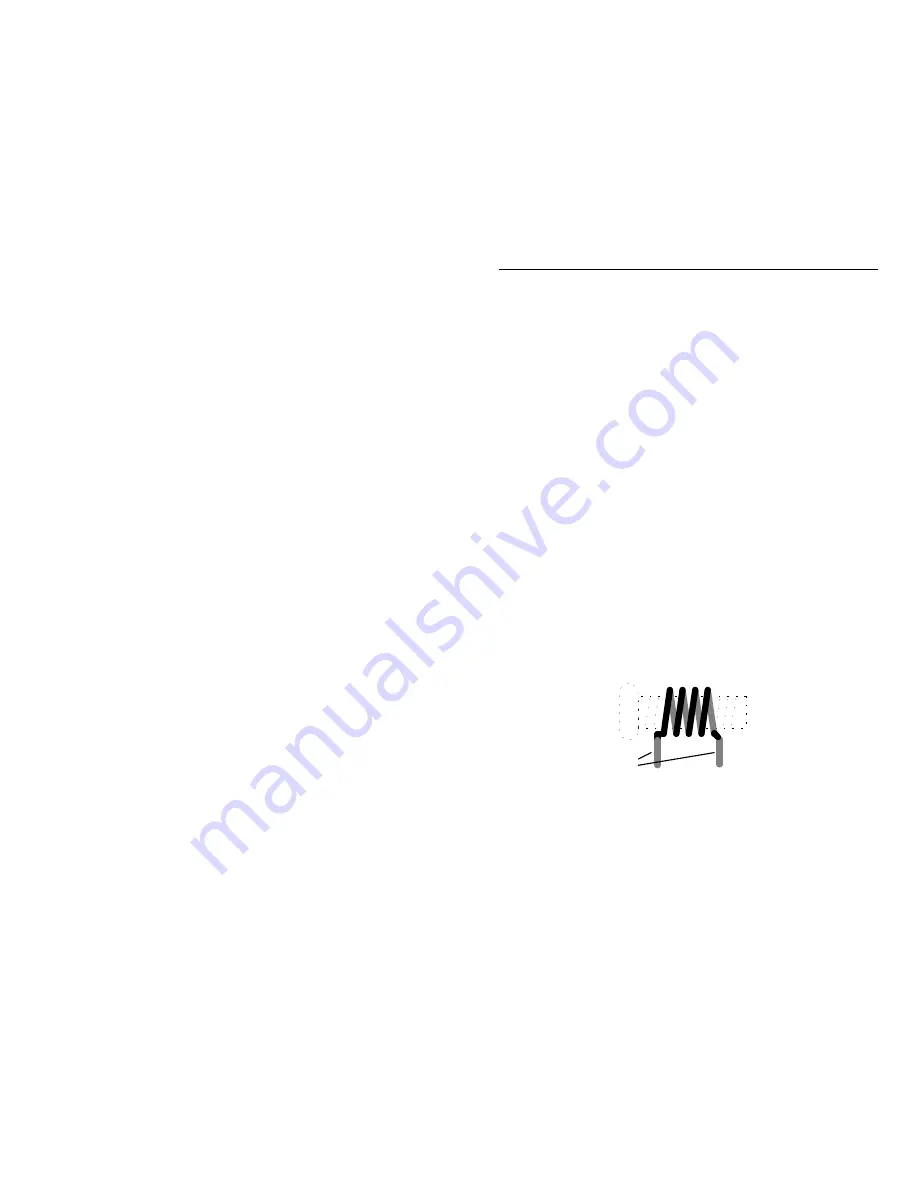

4. Take one length of wire and, while grasping both ends firmly,

carefully wind four (4) full turns over the winding form--as shown.

The wire should conform into the thread grooves.

6-32 screw thread

4-turns #24 enameled wire

1/2" leads stripped

and tinned with solder

!

!

5. Remove the coil by unscrewing it from the 6-32 threads. Shape as

shown above, with about 1 wire-width spacing between each turn.

!

!

6. Each lead must be tinned prior to installation. The wire provided with

your kit is coated with enamel insulation formulated to melt at high

temperatures. This quality should allow you to strip, clean, and "tin"

each coil lead in a single operation. To prepare each lead, hold a hot

soldering iron tip against it for several seconds while applying a small