14

15

Operation

Operation

DC PULSE

SERIES

EQUIPMENT

DC PULSE

SERIES

EQUIPMENT

14. Pulse Button

Press the PULSE button to toggle Pulse On and OFF.

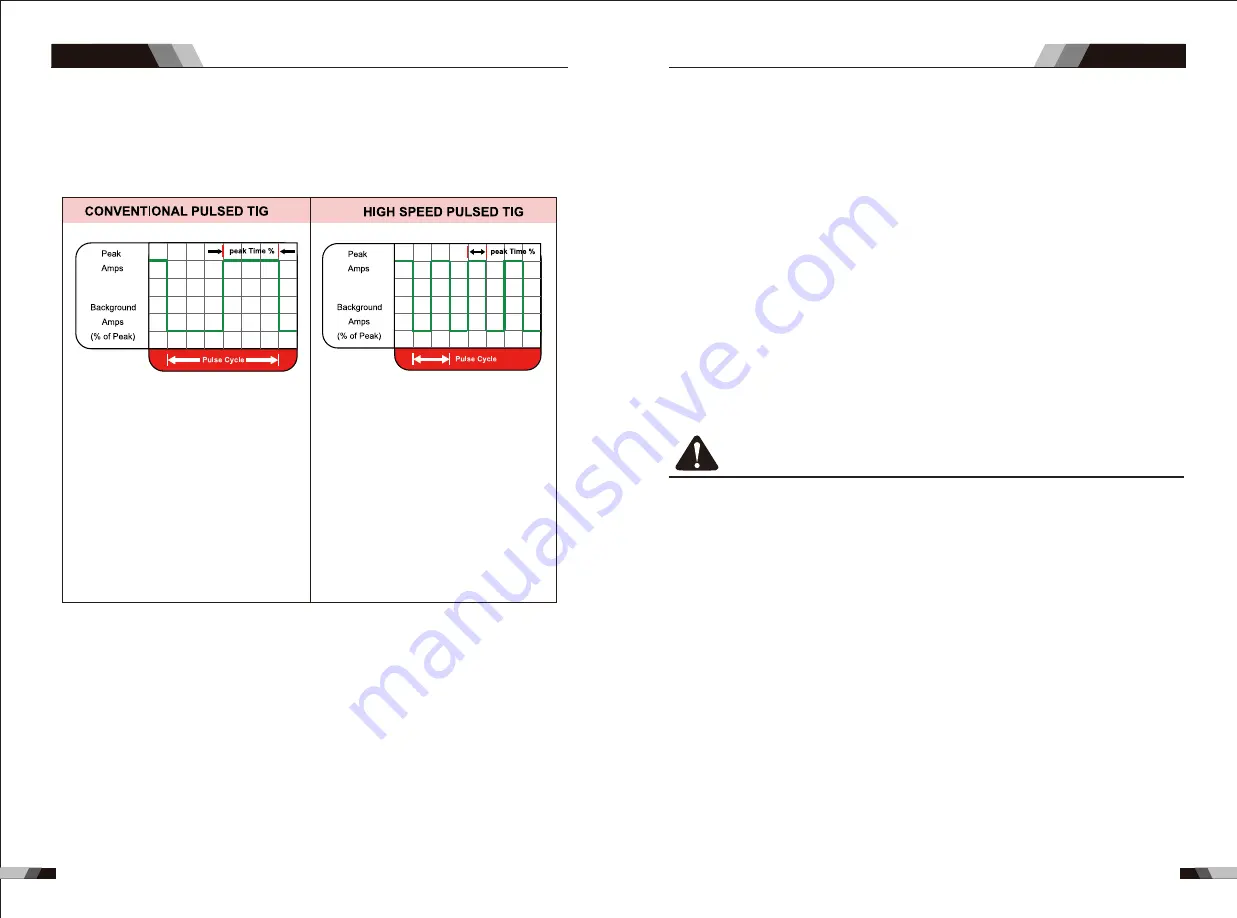

Typically from 1 to 10 PPS. Provides a heating

and cooling effect on the weld puddle and can

reduce distortion by lowering the average

amperage. This heating and cooling effect also

produces a distinct ripple pattern in the weld

bead. The relationship between pulse frequency

and travel speed determines the distance

between the ripples. Slow pulsing can also be

coordinated with filler metal addition and

increase overall control of the weld puddle

In excess of 40 PPS, Pulsed TIG becomes more

audible than visible-causing increased puddle

agitation for a better as-welded microstructure.

Pulsing the weld current at high speeds-between

a high Peak and a low Background amperage-

can also constrict and focus the arc.This results

in maximum arc stability, increased penetration

and increased travel speeds(Common Range:

100-500 PPS).

The Arc-Sharpening effects of high speed

pulsing are expanded to new dimensions. The

ability to pulse at 5,000PPS further enhances

arc stability and concentration potential-which

is extre mely beneficial to automation where

maximum travel tspeeds are required.

13. Process Selection Button

The process selection control is used to select the desired welding mode. Two modes

are available, GTAW (TIG) and MMA (Stick) modes.

16. Positive Welding Terminal

Positive Welding Terminal. Welding current flows from the Power Source via heavy

duty bayonet type terminals. It is essential, however, that the male plug is inserted

and turned securely to achieve a sound electrical connection.

17. Negative Welding Terminal

Negative Welding Terminal. Welding current flows from the Power Source via heavy

duty bayonet type terminals. It is essential, however, that the male plug is inserted

and turned securely to achieve a sound electrical connection.

19. 5 Pin Control Socket

The 5 pin receptacle is used to connect a trigger switch or remote control to the welding

Power Source circuitry:

To make connections, align keyway, insert plug, and rotate threaded collar fully clockwise.

18. Shielding Gas Outlet

The Shielding Gas Outlet located on the front panel is a fast connection of a suitable

TIG Torch.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug

being fused in the terminal.

15. Current adjusting button/functions choosing

Clockwise rotate to enlarge the current, and anti-clockwise rotate to reduce the current.

If you need to choose different programming parameters (the eighth mark), press the

button and release it to choose different functions.

20. Power switch

before using the machine. Pull the switch to the closure state of “AN” to operate the

machine, and pull the switch to “AUS” after use. Turn off the power input, and the machine

will stop operating.

21. Gas input port

The gas port is connected with the gas valve output port. After connection, check whether

there is gas leakage.

22. Program downloading port

Change the program downloading connection port, and use the plastic cover to prevent

the dust from polluting and oxidizing the port after use.