9

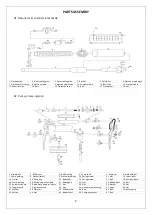

PARTS ASSEMBLY

01.

Resonator & chemical Inlet nozzle

1. Ejection pipe

2. Inner cooling pipe

3. Outer cooling pipe

4. Bracket

5. Safety net

6. Ejection nipple plate

7. Ejection buffer spring

8. Ejection nipple

9. Ejection nipple tube

10. Straight nipple

11. Ball valve

12. Straight nipple

13. Chemical pipe

14. Bolt

15. Protective cover

16. Bolt

17. Flat washer

18. Nut

02

Pump, Frame, Ignition

1. Handle ball

2. Buffer hose

3. Buffer spring

4. Pump shaft

5. Pump nut

6. Washer(large)

7. Pump packing

8. Washer(small)

9. Washer(medium)

10. Spring washer

11. Nut

12. Under cover

13. Piercer

14. Pump peg

15. Body(left)

16. Spring washer

17. Bolt

18. Pump(cylinder)

19. Pump rear peg

20. Hand pump hose nipple

21. Body(right)

22. Nut

23. Middle plate

24. Bolt

25. Automatic pump

26. Automatic pump air nipple

27. Nut

28. Nut

29. Washer

30. Nut

31. Toggle switch

32. Ignition switch

33. Nut

34. Hose protection spring

35. Hose

36. Nut

37. Washer

38. Vibrator

39. Bottom plate

40. Bolt

41. Bolt

42. Battery grip

43. Battery

44. Nut

45. Butterfly nut

46. Charging consent

47. Bolt