10

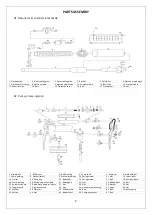

03. Chemical & Fuel Tank

04. Carbure

tt

or

1. Venturi

2. Upper Gasket

3. Cone sha

ft

4. Petrol valve board 5. Petrol valve

6. Petrol valve support

7. Spring washer

8. Bolt

9. Lower Gasket

10. Engine

11. Ejec

ti

on nozzle

12. Nozzle

13. Ring

14. Nut

15. Engine upper pipe

16. Plug

17. Plug cap

18. Metal grip

19. O-ring

20. Engine rear peg

21. Reducer

22. Run tee

23. Elbow

24. Explosion pipe

25. Air gasket

26. Washer

27. Air Gasket Bolt

28. Air elbow

29. Extension hose

30. Air gasket bolt

31. Air gasket washer

32. Air gasket nut

33. Air gasket nut

1. Fuel tank

2. Run tee

3. Fuel tank pipe

4. Check valve

5. Rubber check valve

6. T-check valve

7. upper air pipe

8. Oil pressure hose (blk) 9. O-ring

10. Oil tank peg

11. Knocking release

12. Oil tank elbow

13. oil

fi

lter device

14. fuel hose

15. nut

16. nut

17. chemical tank

18. chemical tank

mouth

19. Chemical tank

fitti

ng

20. Chemical tank grip

21. Chemical tank bolt 22. Chemical tank nut

23. Chemical outlet pipe

24. Elbow

25. Chemical amount

control valve

26. Straight nipple

27. Chemical tank

mouth ring

28. Chemical tank

mouth peg

29. Elbow

30. Check valve-1

31. Check valve packing

32. Check valve-2

Unit 13 Riverside Park, Dog

fl

ud Way, Farnham, GU9 7UG. United Kingdom. Tel: +44 (0)1252 757 222. Fax: +44 (0)1483 326 534