INSTALLATION

Series 642

54/113

Edition 2017-11-24

605593EC

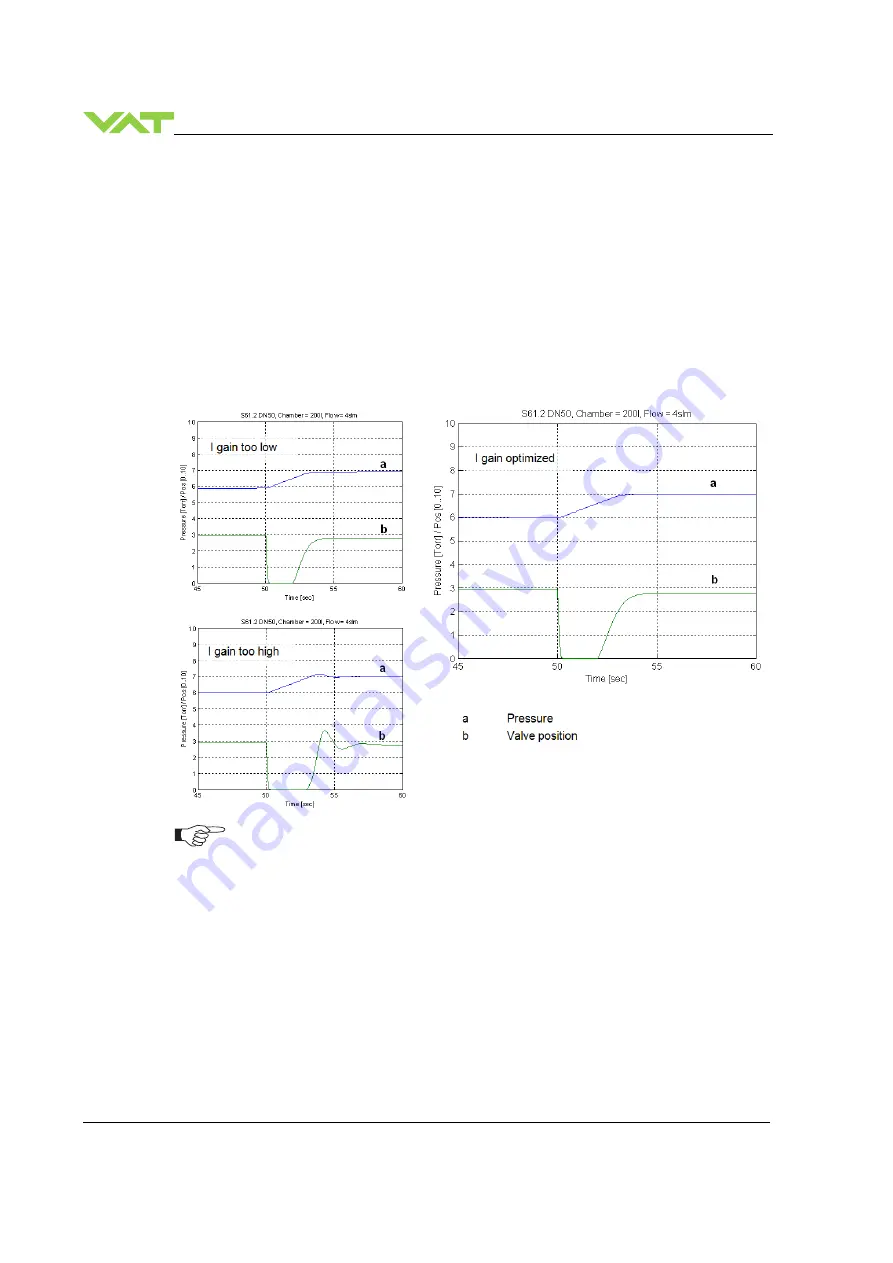

3. Optimizing I gain

While optimizing I gain, the gas flow determined above has to be constant all the time.

Start with P gain set to half of the value found when optimizing P gain and set I gain to 1.0.

Keep the P gain constant.

Set chamber pressure to SP2, wait until the pressure is stable. Set pressure to SP1. If the transition from

SP2 to SP1 results in a significant pressure over shoot or if the valve position does not stabilize, I gain is

to high. If the transition results in a slow asymptotical pressure rise and there is still a constant deviation

to SP2, the I gain is too low.

The optimal value for I gain is found if the transition from SP2 to SP1 result in just a slight pressure over

shoot, a stable valve position and the actual pressure matches SP2 exactly.

Example:

Check control performance over the whole control range with parameters above.

4.7.2.1

Required information for support (in case of unsuccessful tuning procedure):

•

Go to ‘Tools / Create Diagnostic File’ in ‘Control View’ resp. ‘Control Performance Analyzer’ and save

file

•

Pressure / flow / gas conditions to be controlled

•

Chamber volume

•

Pumping speed (l/s) and pump type (e.g. turbo pump)

•

System description

•

Problem description

Send diagnostic file with and all required information to [email protected]