6

1.3

Plumbing Considerations

1.3.1

Cold water supply

General

The Vapanet range of electrode boilers is capable of

operating with a range of “raw mains” water quality. The

water supply should be within the following limits:-

Hardness 50 – 500 ppm

Conductivity 80 – 1000 µS*

PH 7.3 – 8.0

Silica

0

Pressure of between 1.5 - 8 bar.

Chlorine <170 ppm

Water Supply rates

0.25 l/min

LFE05

Do’s

Do

install a stop-valve/Shut-off valve and a strainer close to

the unit.

Do

provide a water supply with sufficient pressure and pipe

size to ensure an adequate flow rate to all units connected

to the system.

Do

use the flexible hose connection with nylon nut provided.

Don'ts

Don’t

use a wrench or other tool to tighten the water supply

connection - the nylon nut and rubber washer provided,

should only require tightening by hand to effect a seal. If

water seepage occurs, undo the nut to wipe the washer clean

and re-seat it.

1.3.2

Drain connection

General

Do's

Do

ensure metal drain and supply water pipework is

grounded electrically close to the unit (a ground/earth stud

is positioned on the underside of the cabinet).

Drain capacity per cylinder and drain tray pump

= pump discharge rate of max 11.8 l/min at 50 Hz.

Power supply 12.2 l/min at 60 Hz.

Do’s

Do

use copper or plastic pipe rated for 110

o

C.

Do

arrange to discharge drain water from the unit into a

trapped and vented drain at a position where flash steam

rising from the drain line vent will not pose a problem for

the Vapac or other equipment.

Do

provide adequate fall for the drain pipe work to allow free

flow of water drained from each unit.

Do

ensure drain line pipe size will accommodate water being

drained at the same time from all the Vapac units which

are connected to it.

Do

ensure drain line has a min full of 5° 1 in 12 pipe (8%) fall

and sized adequately to take all units connected into it at

fall pump flow rate each LFE unit has two pumps one from

drain tray the other from cylinder both have the same flow

rate as above.

Do

run both condensate outlets from unit independently until

both pipes have dropped 100mm before tee together as

shown below.

1.3.3

Drain Tray overflow

The unit is fitted with a drain tray overflow pipe which is not

pumped, this is a pipe from the drain tray direct and requires

a fall to a visual point to indicate the drain tray is full when the

unit is powered off and the drain pump is not working. This is

to prevent damage to ceiling void area.

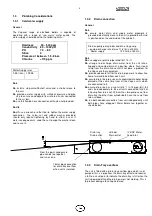

Drain tray

Cylinder

¾” BSP Water

Drain outlet

Drain outlet

Feed inlet

From this point condensate

pipe can be tee together

and run as one.

15mm pipe connection

for drain tray overflow

when unit is isolated.

Summary of Contents for VapaNet LFE Series

Page 19: ...19 3 3 Facia Label symbols 1 ...

Page 21: ...21 ...