Swift1915Z Aura LED Moving Head Beam Wash Light User Manual Swift1915Z Aura LED Moving Head Beam Wash Light User Manual

Tilt Inverse

Select Tilt Inverse, press

ENTER

button to confirm, present mode will blink on the

display, use

UP

and

DOWN

button to select No (normal) or Yes (tilt inverse), press

ENTER

button to store. Press

MENU

button back to the last menu or let the unit idle

one minute to exit menu mode.

P/T Feedback

— Pan/Tilt Feedback

Select P/T Feedback, press

ENTER

button to confirm, present mode will blink on the

display, press

UP

/

DOWN

button to select No (Pan or tilt’s position will not feedback

while out of step) or Yes (Feedback while pan/tilt out of step), press

ENTER

button to

store. Press

MENU

button back to the last menu or let the unit idle one minute to exit

menu mode.

BL.O. P/T Moving

— Blackout while pan/tilt moving

Select BL.O. P/T Moving, Press

ENTER

button to confirm, present mode will blink on

the display, use

UP

and

DOWN

button to select No (normal while pan/tilt moving) or

Yes (blackout while pan/tilt moving), press

ENTER

button to store. Press

MENU

button

back to the last menu or let the unit idle one minute to exit menu mode.

White Balance

Select White Balance, press

ENTER

button to confirm, present mode will blink on the

display, use

UP

and

DOWN

button to select Red, Green or Blue, Once selected, press

ENTER

button, then use

UP

and

DOWN

button to adjust the value from 125 to 255,

press

ENTER

button to store. Press

MENU

button back to the last menu or let the unit

idle one minute to exit menu mode.

Cooling Mode

Select Cooling Mode, press

ENTER

button to confirm, present mode will blink on the

display, use

UP

and

DOWN

button to select Auto (Normal) or Low (Low speed), Once

selected, press

ENTER

button to store. Press

MENU

button back to the last menu or

let the unit idle one minute to exit menu mode.

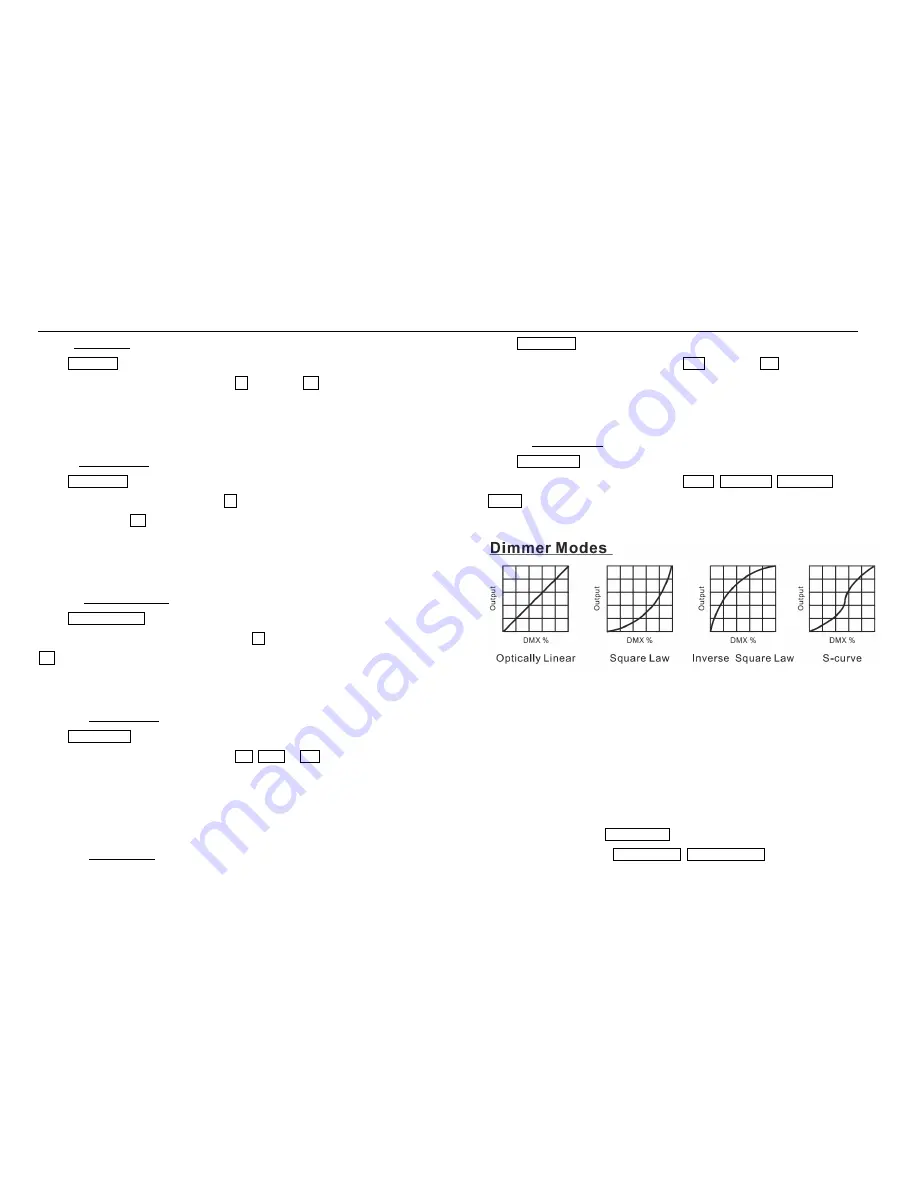

Dimmer Curve

Select Dimmer Curve, press

ENTER

button to confirm, present mode will blink on the

display, use

UP

and

DOWN

button to select Linear , Square Law, Inverse Squ. or

S-curve, Once selected, press

ENTER

button to store. Press

MENU

button back to the

last menu or let the unit idle one minute to exit menu mode.

Linear:

The increase in light intensity appears to be linear as DMX value is increased.

Square Law:

Light intensity control is finer at low levels and coarser at high levels.

Inverse Square Law:

Light intensity control is coarser at low levels and finger at high

levels.

S-cure:

Light intensity control is finger at low levels and high levels and coarser at medium

levels.

Display Setting

Enter

MENU

mode, select Display Setting, press

ENTER

button to confirm, use

UP

and

DOWN

button to select Display Inverse, Backlight Auto Off,

13

12