WIRING

T775A/B/M SERIES 2000 CONTROLLER

5

62-0254–03

Controller Wiring

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring,

or making wiring connections, to prevent electrical

shock or equipment damage.

CAUTION

Do not use 24 Vac power to power any external

loads if 120 Vac or 240 Vac is used to power

the T775A/B/M controller.

CAUTION

A separate earth ground is required.

Equipment damage can result if the earth ground

is not connected. See Fig. 5 and Table 2 on

page 6.

CAUTION

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Ensure that you are properly grounded before

handling the unit.

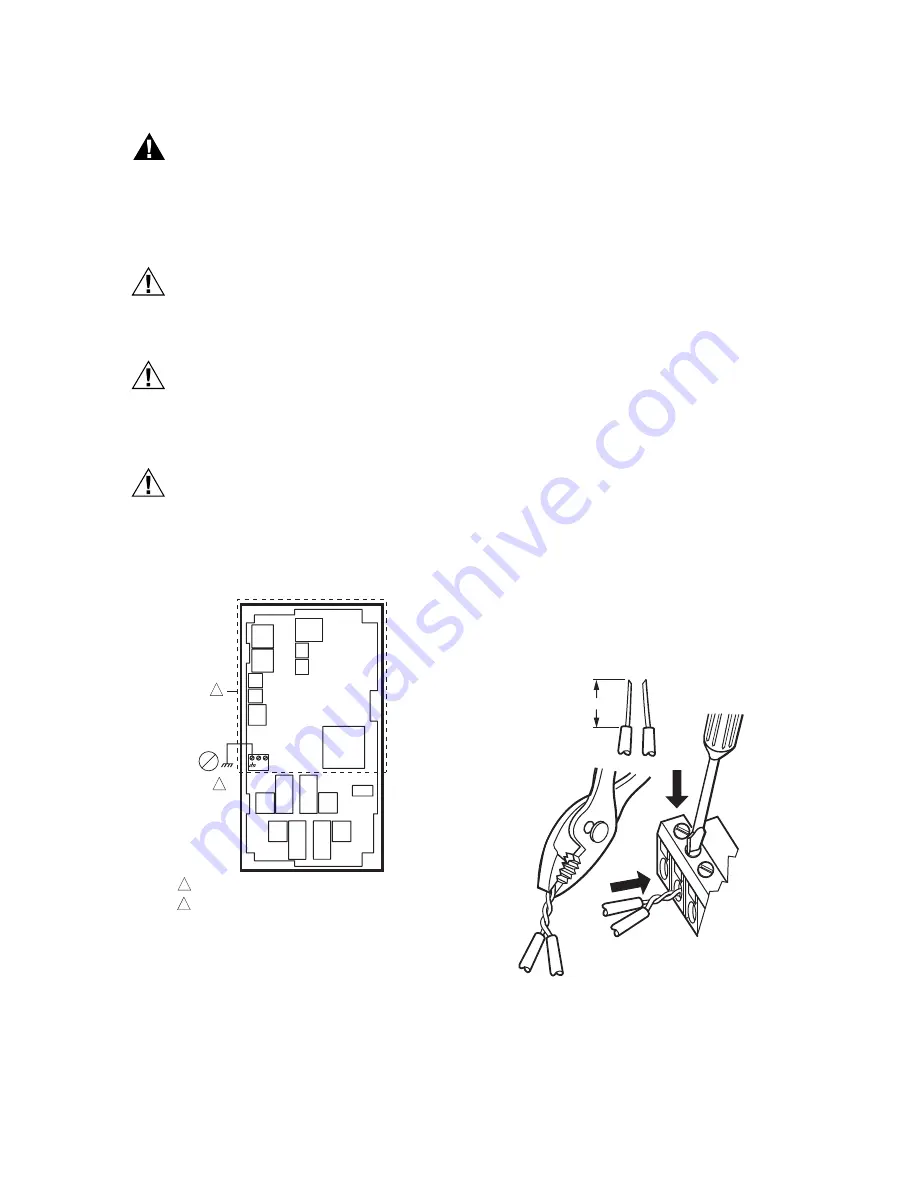

Fig. 5. Earth Ground.

IMPORTANT

Poor wiring practices can cause erratic readings

from the sensor. To ensure proper operation,

ensure that good mechanical connections are

made to both the sensor and the controller.

IMPORTANT

When wiring the input power, only one source of

power can be applied to the T775A/B/M control-

ler (24 Vac or 120 Vac or 240 Vac).

See Fig. 7 on page 6 for locating the appropriate power

input, remote sensors input, low voltage, contact closure,

and load output terminals.

Access to the terminals can be gained through standard

conduit knockouts (A through E in Fig. 7 on page 6)

located around the perimeter of the enclosure:

•

Knockouts A and B should be used only for sensor and

low-voltage wiring.

•

Knockouts C, D, and E can be used to gain access to

the load relay output terminals and 120/240 Vac power

wiring.

Controller Wiring Method

Wire the sensors and outputs, then wire the power

connection.

Each terminal can accommodate the following gauges of

wire:

•

Single wire – from 14 AWG to 22 AWG solid or

stranded

•

Multiple wires – up to two 22 AWG stranded

For 24, 120, or 240 Vac power connections:

Single wire – from 14 to 18 AWG solid or stranded

Prepare wiring for the terminal blocks, as follows:

1.

Strip 1/2 in. (13 mm) insulation from the conductor.

2.

Cut a single wire to 3/16 in. (5 mm). Insert the wire

in the required terminal location and tighten the

screw.

3.

If two or more wires are being inserted into one ter-

minal location, twist the wires together a minimum

of three turns before inserting them to ensure

proper electrical contact.

4.

Cut the twisted end of the wires to 3/16 in. (5 mm)

before inserting them into the terminal and tighten-

ing the screw.

5.

Pull on each wire in all terminals to check for good

mechanical connection.

Fig. 6. Attaching two or more wires at terminal blocks.

C

+

W

1

2

M24296

NO HIGH VOLTAGE. CLASS 2 WIRING ONLY.

EARTH GROUND TERMINAL MUST BE CONNECTED

TO CONDUIT CLAMP LOCALLY.

1

2

1/2 (13)

1.

STRIP 1/2 IN. (13 MM)

FROM WIRES TO

BE ATTACHED AT

ONE TERMINAL.

2.

TWIST WIRES

TOGETHER WITH

PLIERS (A MINIMUM

OF THREE TURNS).

3.

CUT TWISTED END OF WIRES

TO 3/16 IN. (5 MM) BEFORE INSERTING

INTO TERMINAL AND TIGHTENING SCREW.

THEN PULL ON EACH WIRE IN ALL

TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

M24473