10

5.

FULL OPERATING CHECKS

5.1

Check Control Settings

5.1.1.

To help in checking the control positions while

the outer case is detached, place the control bezel over

the gas tap spindle and against the tap bracket.

Temporarily secure to the tap bracket with one of the

screws.

5.1.2.

Fit the control knob over the gas tap spindle.

5.1.3.

Depress the control knob and turn

anticlockwise partially towards the 1/IGN position until

some resistance is felt. Keep depressed at this position

to purge air from the system then, while keeping it

depressed, turn fully to the 1/IGN position. A spark

should be generated at the pilot while turning. The spark

should ignite the pilot.

5.1.4.

When pilot ignition has been achieved, keep the

control knob depressed for approximately ten seconds to

allow the thermocouple probe to warm up and then

release it. If the pilot does not remain alight, ensure that

the air has been purged, that the pilot orifice is clear and

that the thermocouple connections are sound. Replace

the pilot unit if necessary (see servicing section of this

manual).

5.1.5.

Check all the control settings. These are:-

Knob

Position

Burner appearance

1/IGN

Centre section on low. Outer

sections off.

2

Centre section fully on. Outer

sections off.

3

Centre section fully on. Outer

sections on low.

4

Centre and outer sections fully on.

5.2.

Check Reference Pressure

The appliance is pre-set to give the correct heat input at

the inlet pressure shown in section 1 of this manual. No

adjustment is necessary. Check the burner pressure by

fitting a pressure gauge at the test point. The test point is

on the pipe connecting the gas tap to the lower injector.

Check the pressure with the appliance alight and set at

maximum output (Control position 4).

After checking, turn off the appliance. Remove the

pressure gauge and replace the test point sealing screw.

Relight the appliance. Turn to the maximum output

position and test around the sealing screw for gas

soundness with a suitable leak detection fluid.

6.

FINAL ASSEMBLY & CHECKS

6.1

Fit The Outer Case

6.1.1.

Detach the control knob and control bezel.

6.1.2.

Refit the outer case. Make sure that the centre

strip at the top back of the case is located behind the

vertical face of the back panel.

The rearward angled ears near the top corners of the

back panel should be behind the outer case top plate,

(see fig.16).

6.1.3.

Secure the case at the bottom sides with the two

screws previously removed.

6.1.4.

Place the control bezel back in position and

secure it to the gas tap bracket with two screws.

6.1.5.

Fit the control knob over the gas tap spindle.

6.1.6.

Make sure that the coal is not dislodged when

refitting the case.

6.1.7.

Refit the window surround using the two

knurled screws previously removed (The reverse

method to that described in section 3.3.2).

Make sure that

the outer edges of the surround sides are inside the outer case.

6.2.

Test For Spillage

A spillage test must be made before the installed appliance

is left with the customer

.

6.2.1.

Close all doors and windows in the room

containing the fire.

6.2.2.

Light the appliance and set the control knob to

the maximum position (Position 4).

6.2.3.

Leave the appliance on for five minutes.

6.2.4.

There are two types of smoke match holders. One

has a copper finish, the other is plain steel. Please apply

the relevant parts of the spillage test instructions

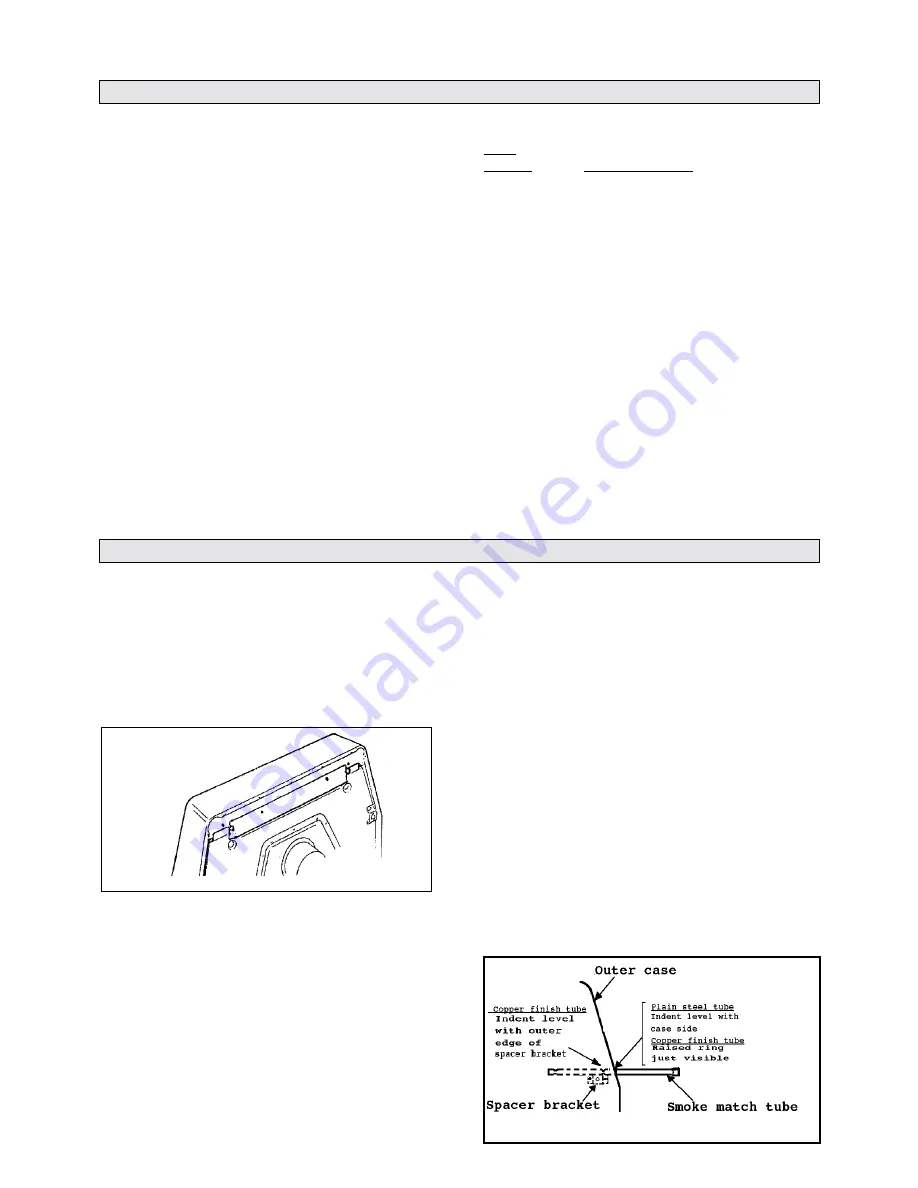

Place the smoke match tube (with lighted match) on top

of the wall spacer bracket at the rear right side of the

appliance.

Copper finish tubes:

Slide the tube in until the second

indent is level with the outer edge of the spacer bracket.

A raised ring round the tube (approx. 25mm from the

indent) should be visible along the casing side (see

fig.17).

Plain steel tubes:

Slide the tube until the indent is level

with the edge of the casing side (see fig.17).

Fig.16 Outer case top location

Fig.17 Smoke match tube position