Page 44

8-8-7

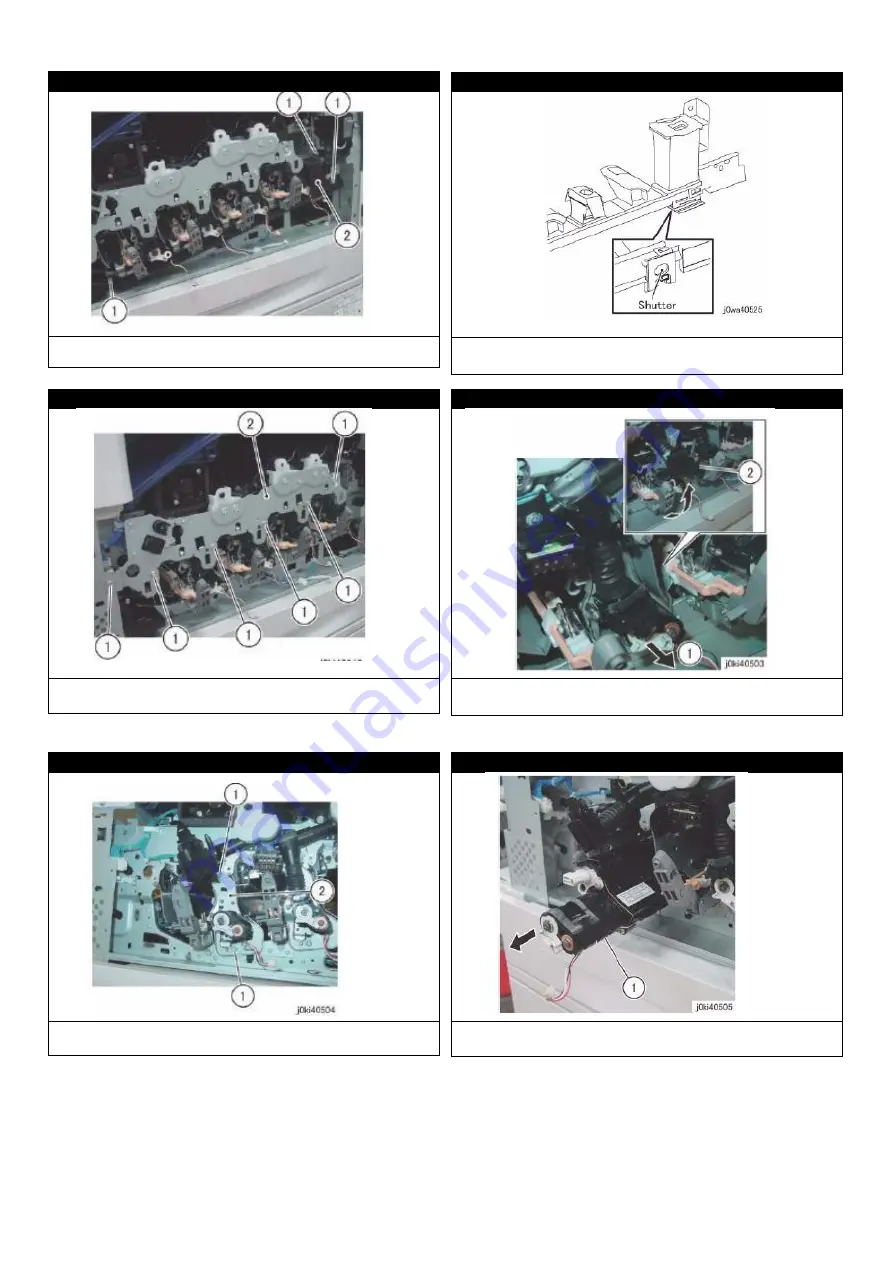

1. Remove the screw; 2. Remove the waste toner assembly.

8-8-8

Confirm the port to the waste toner box is closed. Confirm

this also during installation.

8-8-9

1. Remove the screw; 2. Remove the wall panel.

8-8-10

1. Pull the connecting piece on the developing room inlet;

2. Lift the lower powder tube.

8-8-11

1. Remove the screw; 2. Remove the fixed panel.

8-8-12

Pull the developer unit out.