Pag 41

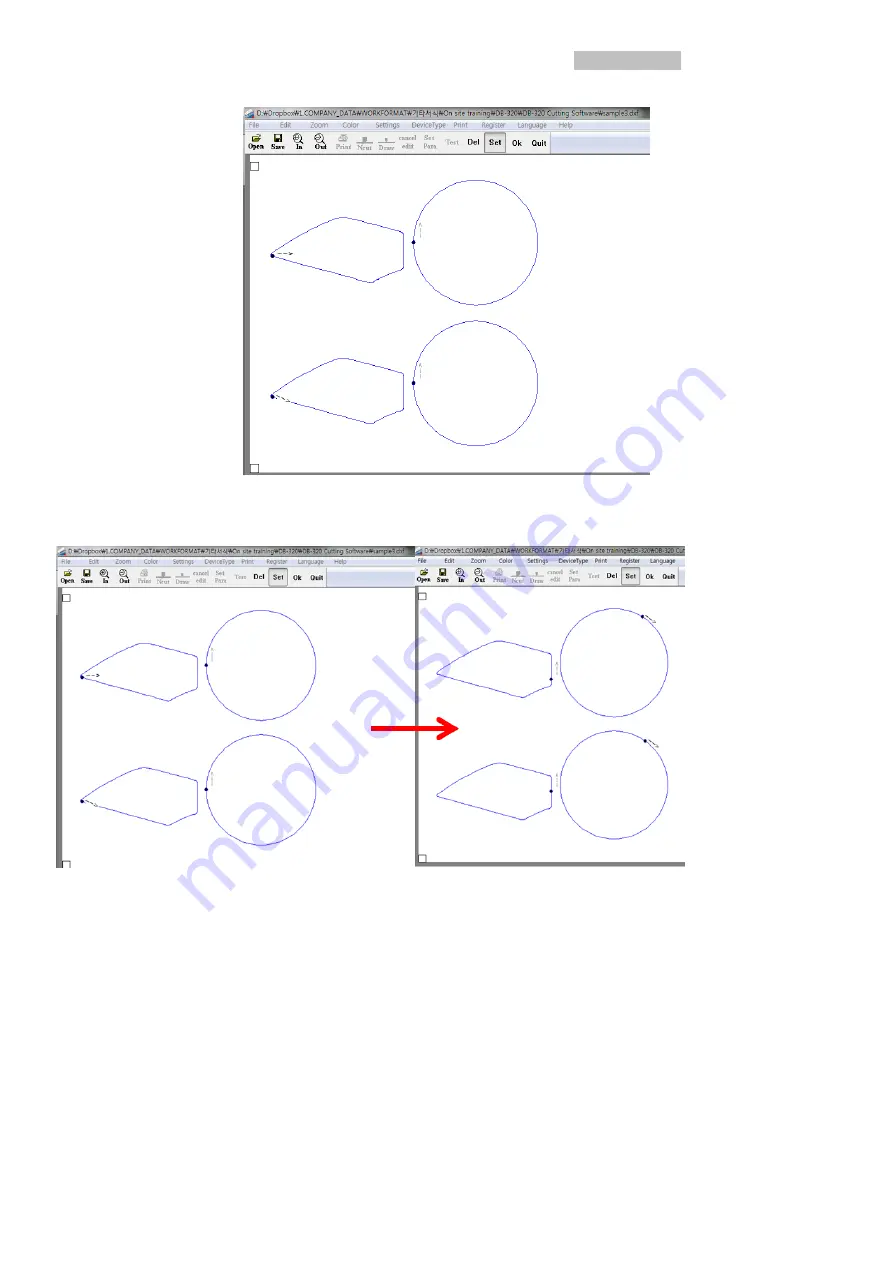

In starting point setup mode, display will be shown differently as below <Picture 5.39> by indicating current

starting points and directions for each object.

< PICTURE 5.39 >

Click any point of objects to change the starting position and click OK button in right end of the GUI.

If you select ‘Drop point knife set’ menu again, you can find starting positions are moved as below.

< PICTURE 5.40 >

If you have slightly mismatching between starting point and ending point, you may easily resolve the

problem by moving the starting point to top/bottom edge against feeding direction as below.