*****INTERNAL*****30 R_D proof- 26.10.2022 / 09:15:46- VaillantGroup\DOC-agt\Brand\VIH_QW_190_6\ENG\OI-II_GB_0020291525

0020291525_04 Installation and maintenance instructions

31

Size of

the outlet

valve

Minimum

diameter

of the

drain pipe

D1

Minimum

diameter

of the

drain pipe

from the

tundish

D2

Maximum

permiss-

ible res-

istance,

inform-

ation

on the

length of

a straight

pipe

Resist-

ance per

elbow or

bend

1/2"

15 mm

22 mm

28 mm

35 mm

9 mm

≤

18 m

≤

27 m

0.8 m

1.0 m

1.4 m

3/4"

22 mm

28 mm

35 mm

42 mm

≤

9 m

≤

18 m

≤

27 m

1.0 m

1.4 m

1.7 m

1"

28 mm

35 mm

42 mm

54 mm

≤

9 m

≤

18 m

≤

27 m

1.4 m

1.7 m

2.3 m

Sample calculation

The following example corresponds to a temperature and

pressure relief valve G1/2 with a drain pipe

(D2)

with four 22

mm elbows and a length of 7 m from the tundish to the drain-

age point. According to the table, the maximum permiss-

ible resistance for a straight length of a 22-mm-thick cop-

per discharge pipe

(D2)

of a thermal expansion relief valve

G1/2 is 9.0 m. The resistance of the four 22 mm elbows,

which are each 0.8 m in length, must be subtracted from this,

i.e. a total of 3.2 m. The maximum permitted length is ac-

cordingly 5.8 m and is therefore below the current length of

7 m. The calculation must therefore be performed using the

second largest size. The maximum permissible resistance

for a straight length of a 28-mm-thick pipe

(D2)

of a thermal

expansion relief valve G1/2 is 18 m. The resistance of the

four 28 mm elbows, which are each 1.0 m in length, must be

subtracted from this, i.e. a total of 4.0 m. The maximum per-

mitted length is accordingly 14 m. As the current length is

7 m, a 28 mm copper pipe

(D2)

should be selected.

Where a single common discharge pipe serves more than

one system, it should be at least one pipe size larger the

largest discharge pipe (D2) to be connected.

A suitable location for the drain pipe terminal is, for example,

beneath a fixed mesh above the odour trap in a soakaway

with a siphon. Low drain pipework, for example up to

100 mm above external surfaces (car parks, meadows, etc.)

can be used provided that it is protected by a wire fence

or something similar to prevent children from coming into

contact with the waste water and provided that the system

is not visible. Do not install any valves or stopcocks on the

drain pipework.

Make sure that the drain pipe from the tundish to the drain

has a constant downward gradient of at least 1:200. The

drain pipe for the heat generator expansion relief valve can

be connected to the horizontal drain pipe for the cylinder

behind the tundish using a T-piece.

The discharge pipe should not be connected to a soil dis-

charge stack unless it can be demonstrated that the soil dis-

charge stack is capable of safety withstanding temperatures

of the water discharged, in which case, it should:

–

contain a mechanical seal, not incorporating a water trap,

which allows water into the branch pipe without allowing

foul air from the drain to be ventilated through the tundish

–

be a seperate branch pipe with no sanitary appliances

connected to it

–

if plastic pipes are used as branch pipes carrying dis-

charge from a safety device, they should be either poly-

butalene or crosslinked polyethylene complying with na-

tional standards as Class S of BS7291-2:2006 or Class S

of BS7291-3:2006 respectively

–

be continuously marked with a warning that no sanitary

appliances should be connected to the pipe.

Note

Plastic pipes should be joined and assembled with

fitting appropriate to the circumstances in which

they are used as set out in BS EN ISO 1043-

1:2002 Plastics. Symbols and abbreviated terms.

Basic polymers and their special characteristics.

Where pipes cannot be connected to the stack it

may be possible to route a dedicated pipe along-

side or in close proximity to the discharge stack.

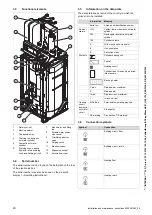

5.6.3

High-level drain

Installing the highest drain is permitted as long as this does

not present a danger to anyone in or outside the building at

the drain point. Examples of points to consider when decid-

ing whether a location is suitable for the highest drain:

–

The possibility (taking the wind into account) that a per-

son might stay in the area where the water is drained

for a prolonged period of time, and, if this is the case,

whether the water is sufficiently cooled by that point to

pose no danger. The thermal conductivity of the material

surfaces, the climatic conditions, the installation location

and the drain pipework direction can, to different extents,

contribute to reducing the temperature of the water that is

being drained.

–

The position of the windows and other openings.

–

The probability of prams being under the drain opening.

–

The resistance of the surface to hot water.

–

The possibility of ice formation if water drains onto ac-

cess paths.

5.7

Installing the drain pipe on the expansion

relief valve

1.

Install the drain pipe with a continuous downwards

incline in a frost-free environment.

2.

Ensure that the size of the drain pipe corresponds to

the size of the expansion relief valve that has been

checked with the type sample.

3.

Ensure that the drain pipe has a maximum of two el-

bows and a maximum length of 2 m.

4.

Make sure that the end of the pipe is visible.

5.

Terminate the drain pipe in such a way that escaping

water or steam cannot cause injury to persons or dam-

age to electronic components.

6.

Open the expansion relief valve regularly in order to re-

move any scale deposition and ensure that the device

is not blocked.