Installation and maintenance instructions for uniSTOR 0020111105_00

17

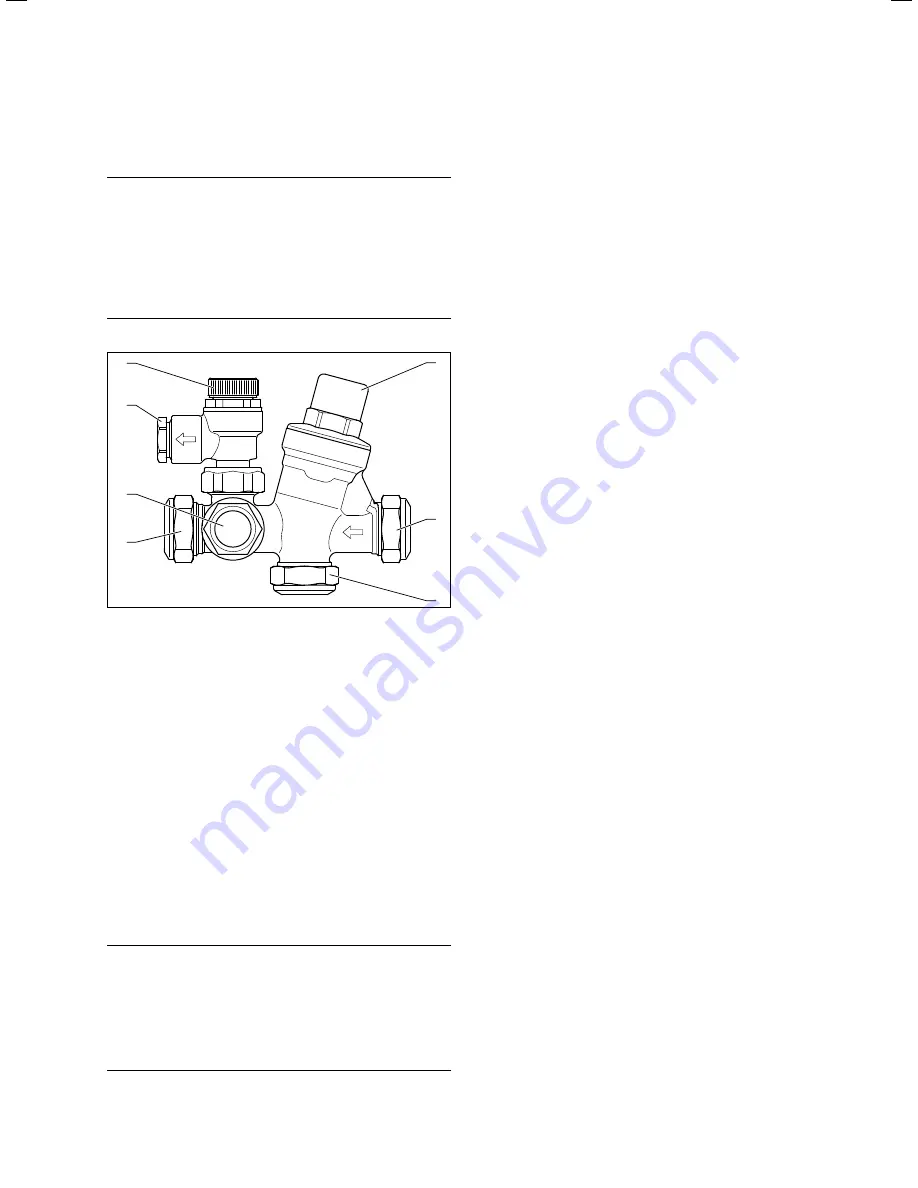

5.3.2 Mounting the safety assembly

b

Caution!

Risk of damage to the cylinder as a

result of excess pressure!

Excess pressure can cause the cylinder to

burst.

>

Make sure that there is no stop valve ins-

talled between the safety assembly

and the cylinder.

1

2

3

4

5

7

6

Fig. 5.4 Safety assembly

Key

1 Pressure reducing valve with line strainer

2 Cold water inlet

3 Pressure-controlled cold water inlet

4 Cylinder

connection

5 Hot water expansion vessel connection

6 15 mm expansion relief valve connection

7 Expansion relief valve

>

During the installation process, position the valves so

that you are able to connect the 15 mm connection (

6

) of

the expansion relief valve (

7

) with the tundish. Note the

direction of flow, which is marked on the safety assembly

with arrows.

i

The safety assembly must be installed horizon-

tally with the expansion relief valve facing

upwards (

¬ fig. 5.4

) in order to prevent the

build-up of dirt.

b

Caution!

Risk of damage to the cylinder as a

result of excess pressure!

Excess pressure can cause the cylinder to

burst.

>

Make sure that the expansion relief valve

outlet is not covered or closed.

>

Mount the discharge pipe of the expansion relief valve

with a constant slope to the outside. The discharge pipe

must finish at a safe and visible point where there is no

danger of it freezing up and where it poses no risk of

injury to persons.

>

Actuate the expansion relief valve regularly to prevent

calcification.

>

Connect the cylinder to the cylinder connection (

4

).

>

For the pipe from the main stop valve of the building to

the cylinder, use copper piping with a diameter of at

least 22 mm to ensure that the cylinder is as efficient as

possible. This is particularly important for installations

with a balanced cold water inlet (

3

).

>

Mount the safety assembly in the cold mains inlet on the

cylinder.

>

If necessary, establish the connection to the cold water

inlet (

3

) with pressure compensation of the safety

assembly.

>

Depending on the fittings used and the type of the draw-

off points, it may be necessary to install a backflow pre-

venter in the pressure-controlled cold water inlet.

i

If you mount the safety assembly above the cyl-

inder, you do not need to drain the cylinder in

order to maintain the safety assembly. Make

sure there is sufficient space for maintenance

and connection of the discharge pipe of the

expansion relief valve.

When the discharge pipes are connected, the expansion

relief valve may not be more than 600 mm away from

the temperature and pressure relief valve (

¬ fig. 5.5

).

5.3.3 Mounting the expansion vessel

The Vaillant domestic hot water cylinder is delivered

with an external expansion vessel.

Connect this expansion vessel to the installed safety

assembly as follows:

>

Screw the expansion vessel directly to the safety assem-

bly via the provided connection (

5

) or

>

Connect the expansion vessel with the safety assembly

via a copper pipe or suitable hose line. Make sure the

expansion vessel is supported sufficiently.

>

Use the supplied wall bracket if you want to mount the

expansion vessel to a wall.

i

In regions with high water pressure (4 bar or

more), you can also connect the mixer tap for a

bath or shower to the cold water inlet with pres-

sure compensation (3) of the safety assembly.

This ensures that the hot and cold water supply

to the mixer tap have the same pressure. You

should install the cold water supply for all other

connections using a T-piece before the safety

assembly in the cold mains inlet to the cylinder.

Installation 5