24

Installation and maintenance instructions 0020213394_05

8.5

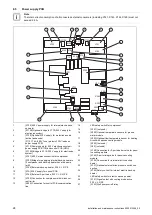

Power supply PCB

Note

The total current consumption of all connected external consumers (including X141, X143, X144, X145) must not

exceed 2.4 A.

X102

X110B

X120

F1

X110

X110A

X101

X145

X1A

X144

X105

X20A

LED

LED

X201

X200

X203

X202

X90

X140

X142

X104

X131

X750

X141

X143

X103

1

2

3

4

5

6

7

8

10

9

11

24

23

26

25

13

14

15

16

17

18

20

19

21

22

12

27

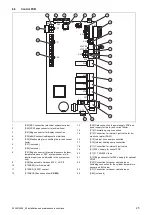

1

[X102] 400 V power supply for internal electric back-

up heater

2

[X110B] Optional bridge to X110 (230 V supply for

electronics system)

3

[X120] Optional 230 V supply for protection anode

(active tank anode)

4

[F1] F1 T 4A/250 V fuse (protects 230 V loads on

power supply PCB)

5

[X110] Power supply for 230 V electronics system

–

power supply PCB (TB) and control PCB (HMU)

6

[X110A] Bridge to X110 (230 V supply for electronics

system)

7

[X101] 400 V mains connection for compressor

8

[X103] Bridge for supplying internal back-up heaters

(if compressor and back-up heater have the same

tariff)

9

[X145] External back-up heater, 230 V, L N PE

10

[X1A] 230 V supply for control PCB

11

[X144] External 3-port valve, 230 V, L S N PE

12

[X105] Connection for compressor with in-rush cur-

rent limiter

13

[X20A] Connection for control PCB communication

line

14

LED safety switch for compressor

15

[X201] (not used)

16

[X200] Optional temperature sensors for ground

water module

17

[X203] Optional flow temperature sensor for heating

circuit with passive cooling module

18

[X202] (not used)

19

[X90] (not used)

20

[X140] Connection for 3-port diverter valve for pass-

ive cooling module

21

[X142] 3-port mixing valve for passive cooling

module

22

[X104] Connection for internal electric back-up

heater

23

[X131] Optional external brine pressure switch con-

nection

24

[X750] Safety cut-out for internal electric back-up

heater

25

LED safety switch for electric back-up heater

26

[X141] Signal output with cooling mode active,

230 V, L N PE

27

[X143] Well pump cut-off relay