9 Inspection and maintenance

22

Installation and maintenance instructions ecoCRAFT exclusive 0020149561_01

8.

Explain to the operator how to check the required sys-

tem pressure and the measures for filling and purging

the heating installation, where required.

9.

Instruct the operator that, when filling the heating in-

stallation, the local water quality must be taken into ac-

count.

10. Inform the operator of the correct (efficient) settings

for temperatures, controllers, and thermostatic radiator

valves.

9

Inspection and maintenance

▶

Disconnect the product from the power mains.

Note

If inspection and maintenance work is neces-

sary when the main switch is switched on, this

is indicated in the description of the mainten-

ance work.

▶

Close the gas isolator valve.

▶

Remove the front casing. (

→

Page 10)

▶

Carry out all inspection and maintenance work in the

order shown in the table "Overview of inspection and

maintenance work".

Inspection and maintenance work

–

Overview

(

→

Page 34)

9.1

Observing inspection and maintenance

intervals

Proper regular inspections and maintenance (once a year)

combined with the exclusive use of genuine spare parts are

decisive factors in ensuring smooth operation and long work-

ing life for the product.

We recommend taking out an inspection and maintenance

contract.

Inspection

The inspection is intended to determine the actual condition

of the product and compare it with the target condition. This

is done by measuring, checking and observing.

Maintenance

Maintenance is required in order to eliminate any deviations

of the actual condition from the target condition. This is nor-

mally done by cleaning, setting and, if necessary, replacing

individual components that are subject to wear.

9.2

Procuring spare parts

The original components of the product were also certified

by the manufacturer as part of the declaration of conformity.

If you use other, non-certified or unauthorised parts during

maintenance or repair work, this may void the conformity of

the product and it will therefore no longer comply with the

applicable standards.

We strongly recommend that you use original spare parts

from the manufacturer as this guarantees fault-free and safe

operation of the product. To receive information about the

available original spare parts, contact the contact address

provided on the reverse of these instructions.

▶

If you require spare parts for maintenance or repair

work, use only the spare parts that are permitted for the

product.

9.3

Checking the CO/CO

₂

ratio

Note

Checking/adjustment of the CO/CO

₂

Ratio is re-

quired in the following instances:

- replacement of gas valve.

- or if an incorrect combustion is suspected

- during annual maintenance

1.

Make sure that there is an opening for the CO/CO

₂

measurement in the flue pipe. Connect a suitable flue

gas analyser to this opening to establish the combus-

tion performance of the boiler.

Note

The maximum draught should not exceed 20

Pa, as otherwise the results of the CO/CO

₂

measurement in minimum load will be in-

valid. If necessary you can remove the cover

of the inspection opening in the external ex-

haust gas ducting during the measurement.

Then replace it after the measurement.

2.

Remove the front casing.

3.

Start the testing program

P.1

for full mode (

→

Page 15).

–

Wait at least 5 minutes until the boiler reaches its

operating temperature.

4.

Measure the CO/CO

₂

Ratio at the flue pipe. Compare

the measured value with the corresponding value:

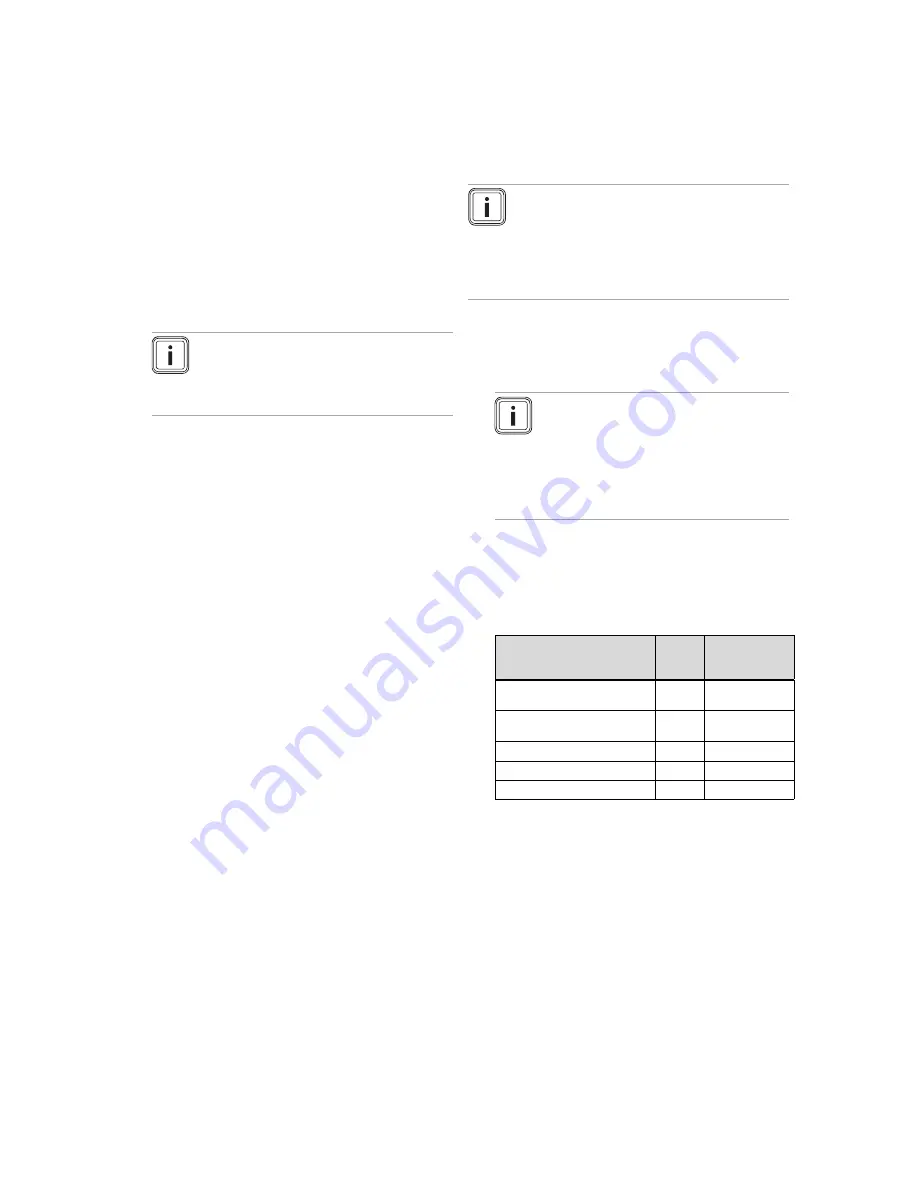

Settings for

VKK GB 806/3-E R1 - VKK

GB 2806/3-E R1

Unit

Natural gas (H)

Tolerance

CO

₂

after 5 minutes full load

mode (P.1)

Vol.

–

%

9.3

±

0.2

CO

₂

after 5 minutes minimum

load mode (P.2)

Vol.

–

%

9.0

±

0.2

Set for Wobbe index W

s

kWh/m

³

15.0

CO value with full load

ppm

< 200

CO/CO

₂

< 0.0023

5.

Start the testing program

P.2

for minimum load.

–

Wait at least 5 minutes until the boiler reaches its

operating temperature.

6.

Measure the CO/O

₂

Ratio at the flue pipe. Compare the

measured value with the corresponding value.

7.

If all these points are as required, leave the test mode.

8.

If one of the flue gas values is greater than the accept-

able values then proceed as described in the following.