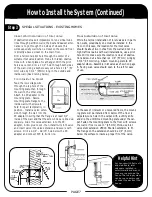

The power unit should be mounted on an outside wall

to minimize the length of the exhaust line. Mount the

unit at a height that will provide convenient access to

the dirt receptacle, or about 6 feet (1.8 m) from the

floor to the top of the wall-mounting bracket which

holds the power unit. For proper ventilation and access,

the wall-mounting bracket must be at least 14" (355

mm) from ceiling and 14" (355 mm) from a side wall.

To mount on a masonry wall, use the wall-mounting

bracket as a template to locate two holes on a mortar

joint or on the surface of a cement block. Drill the two

marked holes 1" (25 mm) deep using a 1/4" (6.4 mm)

masonry drill bit.

To anchor, insert a 1/4" (6.4 mm) plastic anchor in

each hole. Secure the mounting bracket to the wall with

two 1" No. 12 (?5.5 x 25 mm) sheet-metal screws.

In anchoring to a wood or plaster wall, locate the wall-

mounting bracket on a stud. Securely anchor bracket to

stud with two No. 14 x 1 1/2" (?6.3 x 38 mm) screws

through the two vertical holes.

Hang Power Unit and Install Exhaust Line

The manufacturer recommends that a muffler be

installed with all power units. Mufflers are sold separate-

ly. Install the muffler vertically in the exhaust line with-

in the building, and extend the exhaust line outside.

The connection of the intake line and wiring to the

power unit will be completed after the balance of the

system is installed

.Electrical Requirements

All Vacuflo Power Units are supplied with a power supply

cord for connection to a grounded receptacle. All wiring

must meet local codes. Warning: When using the system,

electric shock might occur if used on a wet surface.

Grounding Instructions

This appliance must be grounded. If it should malfunc-

tion or breakdown, grounding reduces the risk of elec-

tric shock by providing a path of least resistance for

electric current. This appliance is equipped with a cord

having an equipment-grounding conductor and ground-

ing plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in accor-

dance with all local codes and ordinances.

WARNING!

Electric shock is a risk when the equipment-grounding

conductor is improperly connected. Check with a quali-

fied electrician or service person if you are in doubt as

to whether or not the outlet is properly grounded. Do

not modify the plug provided with the appliance—if it

will not fit the outlet, have a proper outlet installed by a

qualified electrician. This appliance is for use on a nomi-

nal 120-volt circuit. Make sure that the appliance is con-

nected to an outlet having the same configuration as the

plug. No adapter should be used with this appliance.

INSTALLATION OF THE POWER UNIT - NEW & EXISTING HOMES

How to Install the System

Step 1

INSTALLATION OF INLET VALVES –

EXISTING HOMES

Step 2

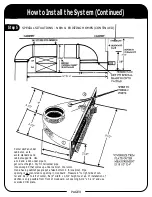

Helpful Hint

Probe for obstructions by insert-

ing a sufficient length of tubing

into the wall before cutting the

inlet valve hole.

The hole in the wall for the inlet valve should be locat-

ed between studs—clear of obstructions such as plumb-

ing, wiring, heating ducts, etc. NOTE: Minimum stud

depth for sufficient clearance of the adapter elbow is 2

3/4" (70 mm).

Determine the exact location of an inlet valve and locate

a point on the floor directly below vertical center of the

desired location. For appearance, the height of the inlet

valves should be centered with the height of electrical

receptacles. Drill a small pilot hole (against the wall)

through the flooring and sub-flooring. The straight sec-

tion of a wire coat hanger cut at an angle makes a good

pilot hole drill bit. (Be careful not to snag carpeting.)

From beneath the floor, this pilot hole will serve as a

guide point from which you can measure over approxi-

mately 2 1/2" (63 mm) to locate and drill a 2 1/4" (57

mm) diameter hole in the center of the sole plate.

Before cutting the 2 1/4" x 3 3/4" (57 mm x 95 mm)

hole in the wall for the inlet valve, drill the 2 1/4" (57

mm) diameter hole up through the sole plate. Using a

flashlight, inspect the interior of the wall to make sure

there are no obstructions. It is also advisable to probe

for obstructions by inserting a sufficient length of tub-

ing into the wall

BEFORE

cutting the inlet valve hole.

PAGE 5