13

13

5

5

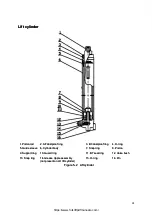

Lifting

Lifting System

System

Fault

Fault

Possible

Possible cause

cause

Remedy

Remedy

Fork carriage and

Fork carriage and

mast tilt without

mast tilt without

operator touching

operator touching

controls

controls

Excessive wear on tilt cylinder seal rings.

Excessive wear on tilt cylinder seal rings.

Replace piston seal rings or

Replace piston seal rings or

cylinder

cylinder

Multi-way valve control valve spring

Multi-way valve control valve spring

inoperative.

inoperative.

Replace

Replace

Fork carriage lift

Fork carriage lift

and tilt action stiff

and tilt action stiff

Piston seized to cylinder wall or piston rod

Piston seized to cylinder wall or piston rod

bent.

bent.

Replace damaged parts

Replace damaged parts

Excessive

Excessive cylinder

cylinder fouling.

fouling.

Flush

Flush

Fork lifting

Fork lifting

movement not

movement not

smooth

smooth

Fork carriage assembly improperly adjusted

Fork carriage assembly improperly adjusted

Adjust clearance between

Adjust clearance between

channel guide rail and side

channel guide rail and side

rollers

rollers

Insufficient clearance between rollers and

Insufficient clearance between rollers and

mast channel.

mast channel.

Adjust roller clearance

Adjust roller clearance

Dirt

Dirt stuck

stuck between

between moving

moving parts.

parts.

Clear

Clear foreign

foreign bodies

bodies

Insufficient lubrication.

Insufficient lubrication.

Smear contact surfaces of

Smear contact surfaces of

guide rail with grease

guide rail with grease

Inner

Inner mast

mast skewed

skewed or

or fork

fork bent.

bent.

Repair

Repair or

or replace

replace

Forks

Forks lift

lift unevenly

unevenly

Lifting

Lifting chains

chains not

not adjusted.

adjusted.

Adjust

Adjust chains

chains to

to same

same tension

tension

Lifting rollers do

Lifting rollers do

not rotate

not rotate

Grease has hardened or rollers are clogged

Grease has hardened or rollers are clogged

with dirt.

with dirt.

Clean and lubricate rollers

Clean and lubricate rollers

Lifting

Lifting rollers

rollers incorrectly

incorrectly adjusted.

adjusted.

Adjust

Adjust

Excessive mast

Excessive mast

noise

noise

Insufficient

Insufficient lubrication.

lubrication.

Lubricate

Lubricate

Fork carriage side rollers unevenly

Fork carriage side rollers unevenly

adjusted. With the mast tilted, side roller

adjusted. With the mast tilted, side roller

strikes mast channel when descending.

strikes mast channel when descending.

Adjust rollers and side

Adjust rollers and side

adjusting shims

adjusting shims

Buffer pad below outer mast does not work

Buffer pad below outer mast does not work

(container forklifts).

(container forklifts).

Adjust gaskets and rubber

Adjust gaskets and rubber

buffer pad so that the piston

buffer pad so that the piston

rod in the cylinder only touches

rod in the cylinder only touches

the bottom of the cylinder after

the bottom of the cylinder after

the inner mast contacts the

the inner mast contacts the

buffer pad.

buffer pad.

Lifting weak or

Lifting weak or

cannot lift

cannot lift

Wear on oil pump gear and pump body

Wear on oil pump gear and pump body

leading to excessive clearance.

leading to excessive clearance.

Replace worn parts or pump

Replace worn parts or pump

Worn seal ring on lift cylinder piston causing

Worn seal ring on lift cylinder piston causing

internal leakage.

internal leakage.

Replace with

Replace with new Y

new Y-ring

-ring

Multi-way valve, safety valve spring

Multi-way valve, safety valve spring

defective.

defective.

Replace spring

Replace spring

Worn multi-way valve lever and valve bod

Worn multi-way valve lever and valve body

y

causing excessive oil leakage.

causing excessive oil leakage.

Replace

Replace

Multi-way valve body leaks oil.

Multi-way valve body leaks oil.

After grinding, reassemble and

After grinding, reassemble and

sequentially tighten screws

sequentially tighten screws

Hydraulic line leaks oil.

Hydraulic line leaks oil.

Compress coupling nut, check

Compress coupling nut, check

sealing gasket and coupling nut

sealing gasket and coupling nut

for damage

for damage

Oil temperature too high, diluted hydraulic

Oil temperature too high, diluted hydraulic

oil, insufficient flow.

oil, insufficient flow.

Change non-compliant

Change non-compliant

hydraulic oil or reduce amount

hydraulic oil or reduce amount

of oil, check reason for high oil

of oil, check reason for high oil

temperature

temperature

Excessive load weight.

Excessive load weight.

Carry out lifting in accordance

Carry out lifting in accordance

with regulations

with regulations

https://www.forkliftpdfmanuals.com/