32

DETAILED SEQUENCE OF OPERATION

The differential air pressure switch is a

safety device which will prevent the boiler

from firing if there is an air intake, boiler

heat exchanger or vent blockage.

1. Turn off service switch, or lower ther-

mostat setting.

2. Remove vinyl caps from Tee.

3. Install testing lines as shown to inclined

manometer or differential pressure gauge

with the ability to read 0.01” to at least

6.0” w.c.

4. Turn on service switch and set ther-

mostat to call for heat.

5. If manometer readings do not corre-

spond to the chart at right, check for

possible causes:

• Blockage or moisture in suction

lines to switch.

• Blockage or moisture in orifice in-

stalled in suction lines to switch.

• Blockage in air intake or vent

pipes.

• Undersized air intake or vent

pipes.

• Loose blower wheel on motor

shaft.

• Incorrect pressure switch or pres-

sure switch setpoint.

• Gas valve out of adjustment.

6. When pressure reading is proper and

the pressure switch is operating prop-

erly, remove testing lines and reinstall

vinyl caps to Tee and 3-way connector.

Boiler Status

Differential Pressure Switch Contacts

Not Running

0”

3.5”

Closed

0.5”

Open

Running With-

out Blockage

(Approximate

min. vent

lengths)

1.00” for Model 125

3.5”

Closed

1.50” for Model 150

0.5”

Closed

1.50” for Model 175

2.00” for Model 200

Running With

Blockage

Greater Than or Equal

To Setpoints

3.5”

Open

0.5”

Closed

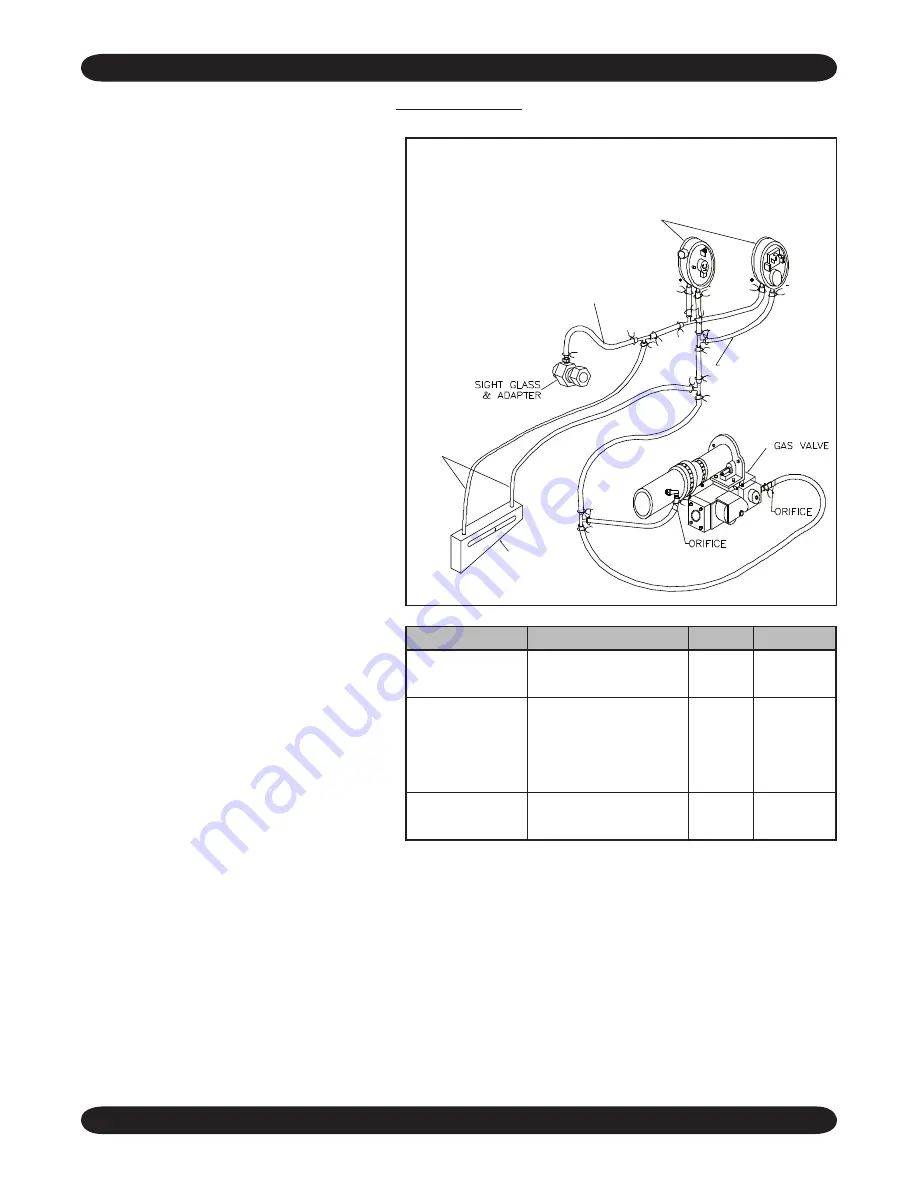

This diagram indicates the locations of the connection

points required to check the differential air pressure.

SERVICE HINTS

ORANGE SILICONE HOSE

MANOMETER

TESTING

LINES

DIFFERENTIAL AIR

PRESSURE SWITCHES

TRANSPARENT WHITE

SILICONE HOSE