38

14.2 Chimney and Chimney Connector

1.

Chimney connector should be kept as short as possible.

Horizontal length of chimney connector should not be

greater than 10 feet.

2.

Type L Vent pipe or other suitable material may be

used for chimney connector if flue temperature is less

than 570° F.

3.

4,5 & 6 section boilers are equipped with a sheet metal

flue collar for attaching 5" diameter chimney connector.

Attach chimney connector to flue collar with 3 standard

sheet metal screws (field supplied).

4.

7 section boilers are equipped with a cast iron flue

collar for attaching 6" diameter chimney connector.

Attach chimney connector to flue collar using furnished

drill bit to drill holes for furnished screws. Vent

Connection Kit (drill bit and screws) furnished in

accessory carton. Predrill to avoid cracking cast iron

flue collar.

5.

Canadian installations require blocked vent safety

switch, included in accessory carton. Refer to separate

instruction sheet for installation. Install on boiler flue

collar prior to installing chimney connector.

6.

Canadian installations require blocked vent safety

switch, included with boiler. Refer to separate

instruction sheet for installation. Install on boiler flue

collar prior to installing chimney connector.

7.

Inspect chimney and connector annually for signs of

debris and corrosion. Loose mortar at base of chimney

may be sign of condensate damage to chimney.

8.

Inspect base of chimney for any signs of seepage.

Discoloration may be a sign of chimney damage. Have

repaired immediately.

9.

Contact qualified service agent immediately to examine

damage and correct. Operation of damaged chimney

may cause venting failure and force flue gases into

living space.

10.

If chimney is to be re-lined, use recommendations in

NFPA31, Appendix E or CSA B139.

14.3 Draft

• Natural draft generated through chimney is dependent

on several factors including, chimney height,

temperature of flue gases, cross section area of

chimney, chimney wall insulation value, dilution air and

total volume of flue gases. Operate boiler for at least 5

minutes before measuring draft.

• Minimum Draft at Breech – Draft induced by the

chimney must create at least a neutral pressure of 0

(zero) inches water column (INWC) at breech. Slightly

negative (i.e. suction) pressure is preferred. Pressure

at breech cannot be positive since this could create

condition that allows flue gas by-products to escape

from draft regulator. Draft is to be measured up stream

of draft regulator. See Burner Specifications.

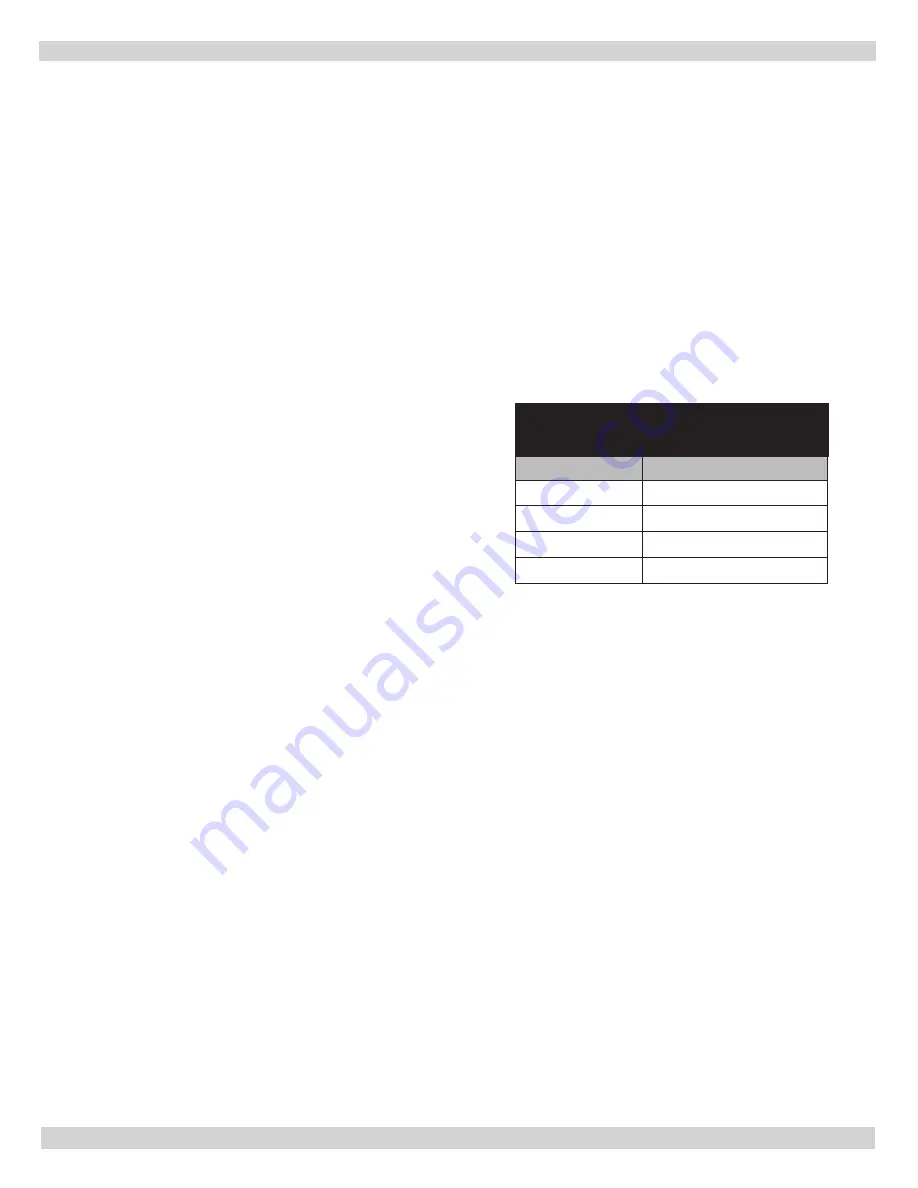

•

Over-fire Draft - Measure pressure at 1/4” NPT test port.

Three pass boilers have higher pressure drop than single

pass. Table 9 shows expected pressure drop between

over-fire and breech. Total pressure drop is difference

between over-fire draft and breech draft. For example,

if over-fire draft = 0.05 INWC and breech draft = - 0.05,

total pressure drop = 0.05 - (-0.05) = 0.10 INWC. See

Figure 33.

Table 9

-

Pressure Drop

Between

Over-Fire & Breech

Sections

Inches WC

4

0.04-0.06

5

0.05-0.08

6

0.09-0.16

7

0.07-0.16

14.4 Stack Temperature

1.

Higher stack temperature, greater amount of draft

generated. Lower stack temperature not only reduces

amount of draft created but also increases possibility

flue gases could condense in chimney connector or

stack.

2.

Consult NFPA 31 and CSA B139 for information for

appropriate choice of venting materials. Chimney may

have to be lined to create sufficient draft, or chimney

may have to be lined to prevent corrosion of masonry

chimney. Consult qualified service agency for chimney

requirements in your area.

3.

Baffles – Efficiency of boiler is based on insertion of flue

baffles supplied with 4,5 & 6 section units. Baffles are

installed in 3rd pass (two inner flueways). Refer to “8 -

Boiler Assembly” for baffle installation. Remove baffles

to increase stack temperature.

4.

Remove baffles if any signs of condensation in chimney

or chimney connector. Removing baffles may not

address condensation.

14 - CHIMNEY AND VENTING CONNECTIONS

PN 240013415 REV A [08/15/2021]