11

4 - CONNECTING SUPPLY AND RETURN PIPING

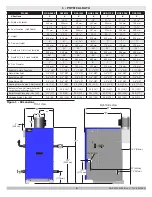

4.5 Supply and Return Requirements

1.

Boiler used in connection with refrigeration system,

install so chilled medium is piped in parallel with boiler

with appropriate valves to prevent chilled medium from

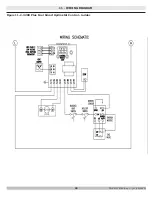

entering boiler. See Figure 4-2 page 12.

2.

Boiler piping system of hot water boiler connected to

heating coils located in air handling units where they

may be exposed to refrigerated air circulation must be

equipped with flow control valves or other automatic

means to prevent gravity circulation of boiler water

during cooling cycle.

3.

Hot water boilers installed above radiation level or

as required by authority having jurisdiction shall

be provided with low water cut-off device (Factory

equipped).

4.

Boiler connected to heating system utilizing multiple

zoned circulators, each circulator must be supplied with

flow control valve to prevent gravity circulation.

5.

Hot water boilers and system must be filled with water

and maintained to minimum pressure of 12 psi.

4.6 Special Conditions

• System piping exposed to freezing conditions: Use

inhibited propylene glycol solutions certified by fluid

manufacturer for use with closed water heating

system. Do not use automotive or ethylene glycol.

• Boiler installed above radiation level (or as required by

authority having jurisdiction). Integral low water cut-

off is provided in boiler.

• Boiler used in connection with refrigeration system.

Install piping in parallel with boiler, with appropriate

valves to prevent chilled medium from entering boiler.

• System piping connected to heating coils located in air

handling unit exposed to refrigerated air circulation.

Install flow control valves or other automatic means

to prevent gravity circulation of boiler water during

cooling cycle.

Do not expose boiler and piping to freezing

temperatures.

Note

WARNING

Asphyxiation hazard! Gradual flueway blockage

resulting from condensate induced corrosion may

block boiler passages, resulting in carbon monoxide

and or flame rollout. Install bypass piping if return

temperature is under 130° F. Failure to follow these

instructions could result in death or serious injury.

!

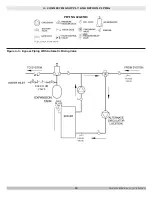

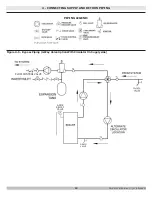

6.

Bypass piping gives ability to adjust boiler water

temperature to fit system or condition of installation.

This method of piping, however, is not typically

required for baseboard heating systems. Typical

installations where bypass piping is required are as

follows:

A. This method is used to protect boilers from

condensation forming due to low temperature return

water (Below 130° F). Generally noticed in large

converted gravity systems other large water volume

systems, and in-floor heating systems. Figures 4-3

and 4-4 pages 13-14

.

B. These methods are used to protect systems using

radiant panels and material they are encased in

from high temperature supply water from boiler and

protect boiler from condensation.

NOTE#1: When using bypass piping, adjust

valves V1 & V2 until desired system temperature

is obtained.

NOTE#2: Bypass loop must be same size piping

as supply and return piping.

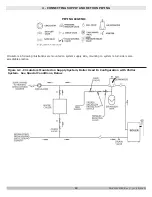

7.

Installation using circulators and zone valves are

shown in

Figures 4-2 through 4-7.

For further piping

information refer to AHRI Installation and Piping

Guide.

8.

Install discharge piping from safety relief valve. See

Warning, Page 9 and Figure 4-1.

PN 240012785 Rev. C [11/15/2020]