14

USI • YOUR SOURCE FOR LAMINATION

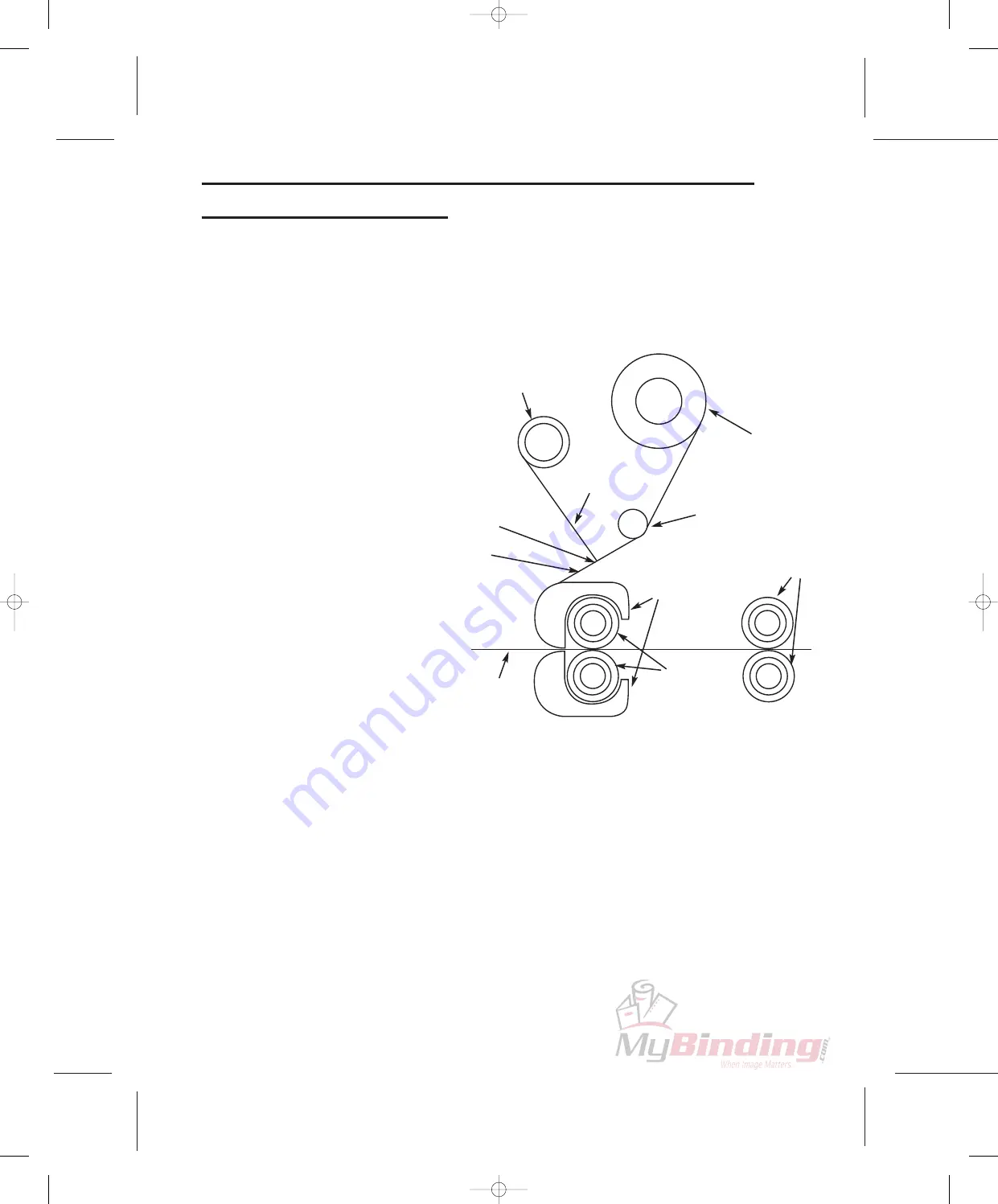

LOADING & OPERATING PRESSURE

SENSITIVE FILM

The MRL42" Roll Laminator/Mounter is equipped with the features

necessary to allow the use of pressure sensitive (cold) film with

release liners for single side lamination. The Waste Rewind will remove

the release liner from the film and wind it onto an empty core, which

can then be disposed.

Turn the heat controls to off and allow machine to cool if necessary

when using cold films.

The pressure sensitive film must be mount-

ed on the upper supply mandrel (3" core

adapters are provided if necessary) and

threaded under the idler roller. An empty

film core should be mounted on the waste

rewind mandrel, and the mandrel mounted

onto the laminator.

A section of scrap substrate that is as least

as wide as the film in use should be started

into the front rollers of the laminator.

Separate the release liner from the film for

a length of about six inches, and adhere

the exposed portion of the film to the sub-

strate that has been started into the

machine. Bring the end of the release liner

under and up to the Waste Rewind man-

drel, and tape the release liner to the spare

core that has been installed over the man-

drel. The Waste Rewind mandrel may be

rotated by hand to assist in the start up.

Slowly advance the motor of the laminator,

guiding the film and substrate to the rear

rollers, while insuring the release liner is

firmly attached to the Waste Rewind core.

The separation point for the film and

release liner should be between the idler

shaft and the point where the film contacts

the heat shoe. The separation point can be

adjusted by the tension knob on the Waste

Rewind Drive Shaft. If the separation point

is past the point where the film contacts the heat shoe, tighten the

tension knob slowly until the separation point approaches the idler

roller. If the separation point is too close to the idler roller, then loosen

the tension knob slowly until the separation moves toward the heat

shoe. The tension setting should need very little adjustment once set,

but should be monitored during operation.

Apply a small amount of tension to the upper supply roll if necessary to

clear any wrinkles occurring on the heat shoe. Once the separation

point is set, lamination is performed normally. Care should be taken to

minimize the gap between successive pieces of substrate being

laminated so that the adhesive from the film is in contact with the lower

roller as little as possible. Cold films utilizing aggressive adhesives will

stick to the laminator’s rollers and potentially wrap around. It is also

recommended to use supply film widths equal to or narrower than the

width of the substrate being laminated.

Note: To encapsulate, run image a second time upside down.

Waste Rewind

Mandrel/Core

Upper Supply Roll

Upper

Idler Roller

Release liner

Separation

Point

Film

Substrate

Front Rollers

Rear Rollers

Heat Shoes