15

REVISION 1.0, 1-19-15

1. Remove membrane element from the right (feed water) side of the membrane housing. Long nose pliers

may be necessary to pull the old membrane element out of the membrane element housing.

2. Lubricate the membrane brine seal and cap o-rings with a non-petroleum based lubricant.

3. Install membrane through the right side (feed water) of the membrane housing with brine seal located on

the feed water side.

4. Push the membrane in the housing from right to left (brine seal on the right). Once the membrane is in

place make sure it is fully seated in the housing.

5. Lubricate the O-rings on the cap and re-install the cap (6, Figure 1.A) on the right side by gently twisting

it, while pushing it onto the housing. Ensure that you do not pinch or fatigue any O-rings while re- in-

stalling the end plug. Push the end plug on until the outer diameter of the plug is flush with the outer di-

ameter of the pressure vessel. Lubricating the inner and outer O-rings will make the cap installation easi-

er.

6. Insert the two half-moon retaining disks until they are fully seated. Subsequently fasten

using a #5 Allen wrench.

7. Reconnect any fittings that may have been disconnected when the membrane pressure vessels were dis-

assembled.

8. To Start-Up the system, please refer to the Initial Start-Up section of this manual.

CAUTION: WET MEMBRANES ARE SHIPPED IN A PRESERVATIVE SOLUTION. THE

MEMBRANES MUST BE FLUSHED FOR AT LEAST 30 MINUTES TO RE-

MOVE THE PRESERVATIVE FROM THE MEMBRANE. DISCARD ALL OF THE

PERMEATE, WHICH IS PRODUCED DURING THE FLUSH PERIOD.

Summary of Contents for L1-200

Page 1: ...1 REVISION 1 0 1 19 15 US Water Systems 300 GPD Premium Wall Mount Light Commercial RO System...

Page 9: ...9 REVISION 1 0 1 19 15...

Page 10: ...10 REVISION 1 0 1 19 15...

Page 11: ...11 REVISION 1 0 1 19 15...

Page 12: ...12 REVISION 1 0 1 19 15 SYSTEM IDENTIFICATION...

Page 17: ...17 REVISION 1 0 1 19 15 SPECIFICATIONS...

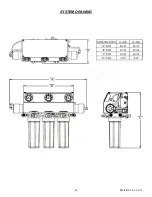

Page 24: ...24 REVISION 1 0 1 19 15 SYSTEM DRAWING...

Page 25: ...25 REVISION 1 0 1 19 15 L1 300 FLOW DIAGRAM...

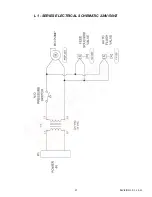

Page 26: ...26 REVISION 1 0 1 19 15 L1 SERIES ELECTRICAL SCHEMATIC 110V 60HZ...

Page 27: ...27 REVISION 1 0 1 19 15 L1 SERIES ELECTRICAL SCHEMATIC 220V 50HZ...