Page 6

www.urethanesupply.com

f.

Weld the front side of the crack

. On the front, it’s usually best

to use the narrow, thin R13 rod. This will tuck down into the

v-groove and retain most of its strength even after it’s been

sanded flush. Use the same process as on the backside to weld

it. However, the R13 will melt and bend much more easily since

it’s thinner. It’s best to focus the heat from the welder a little

farther in front of the point where the rod meets the bumper to

keep the rod from becoming too weak. You need to apply about

a pound of downward pressure on the rod as you do your weld

to make sure the rod fuses properly with the bumper.

g.

Finishing the weld

. Once the weld is completely cool, sand

with 50-80 grit paper in a grinder or DA. Be careful not to sand

too fast; this will just melt and smear the plastic. It’s best to use

a sharp, new piece of paper and slow the sander down a bit to

keep the plastic from melting. Sometimes the repair may be

finished out and feathered with the welding rod, but most often

you’re going to need some filler to fill in the low spots. Please

see our “Book of Plastic Repair” for more information on how

to apply filler on plastic parts.

Welding a broken bumper slot

Because of the strength provided by the nitrogen weld-

ing system, you can make strong repairs even when you

don’t have a lot of surface area to weld to. A perfect ex-

ample is the slots on the edge of the bumper where the

bumper snaps into the quarter panel, like on a Honda

bumper. These often seem to break out when the bump-

er is removed. There’s not enough surface area to make

a good repair with either a two-part system or with the

FiberFlex. Here’s how you fix a torn-out bumper slot.

a.

Clean the plastic

f

irst

. Do this every time

BEFORE you touch it with sandpaper. Clean the

plastic with soap and water first, then with 1000

Super Clean plastic cleaner.

b.

Taper the edges with sandpaper

. Using 50 to 80 grit sand-

paper, remove paint from the area to be welded and taper

the ends down to a point on both sides. This will give you

enough surface area to stick to when you finish the repair.

c.

Apply tape to support rod during weld

. Use the 6481-1 or

6485 aluminum body tape underneath the hole to support

the melted plastic welding rod. You can also clamp a strip

of sheet metal or wood along the edge if that works bet-

ter. Make sure the edge of the support is at the edge of the

plastic so it doesn’t interfere with the clamp and leave room

between the clamps to use the hand seamer as described in

Step F.

Taper both

sides

R13

PP Ribbon

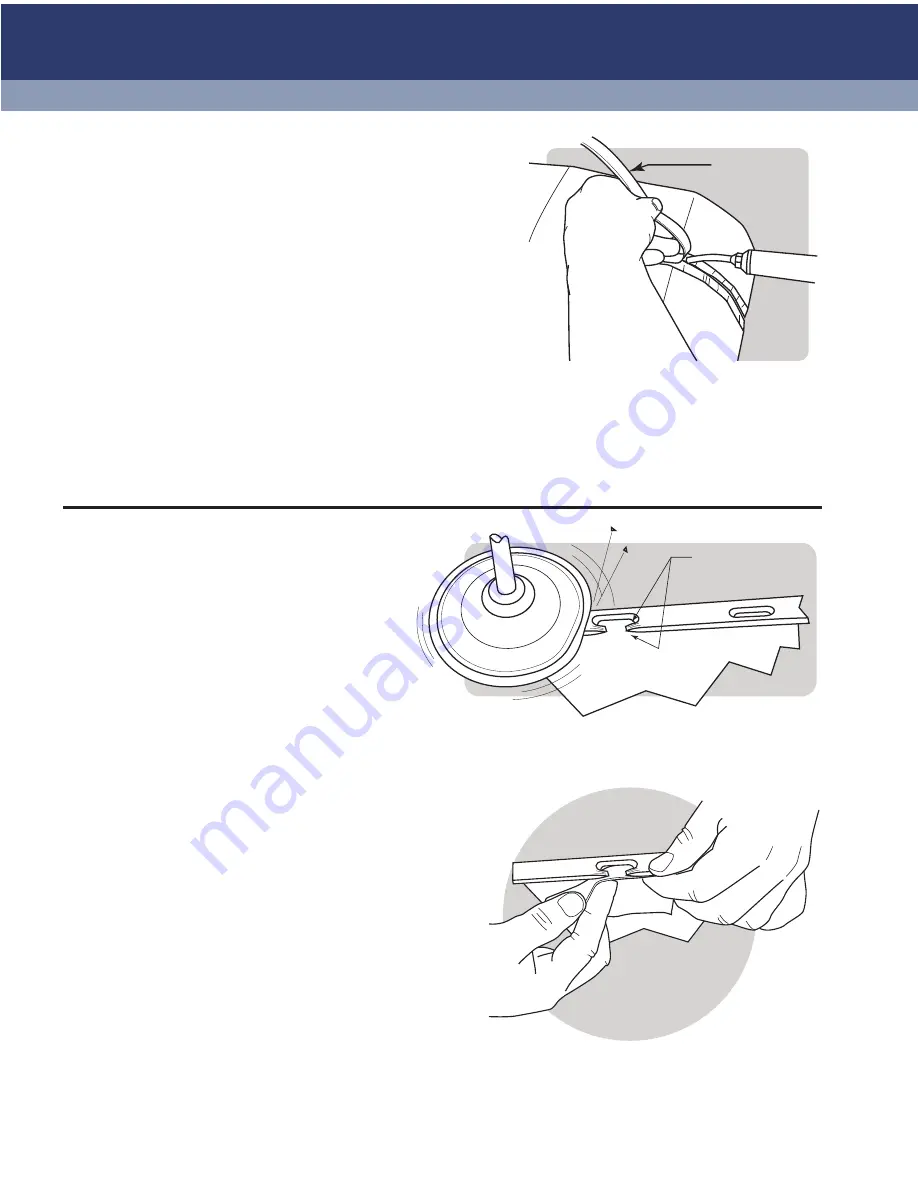

Step F - Welding the front side of the crack with R13 PP

ribbon

Step B - Tapering the edges of the slot to be repaired with sandpaper. Taper

both sides down so the rod has surface area to stick to once sanded.

Step C - Applying aluminum tape to support the melted welding

rod. You can also clamp a wooden stick underneath to provide

extra support.