10

QUICK START

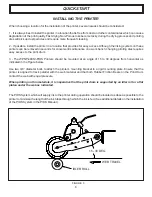

1 -Rotate both the Ink Roll Eccentric Knobs on the Inking

System Cover to the “MIN” position.

In this position, the ink roll will not touch the Anilox Roll

when the cover is reinstalled.

2 -While holding the Inking System Cover in one hand, slide

the Ink Roll onto the Ink Roll Axle.

INSTALLING THE INK ROLL

FIGURE 16

FIGURE 17

Use the round rod or screwdriver used during the ink roll

preparation procedure to position the roll and slide the

roll onto the ink roll axle.

3 -Insert the screwdriver through the hole in the plastic

core and roll the Ink Roll several times across the piece

of cardboard while applying light pressure to remove

the excess ink.

For most applications, you want the roll to be fully saturated

but not dripping wet. If in doubt about the proper saturation

level of the roll during this process, it is better to remove a bit

more ink than not enough. Installing a roll with too much ink

will cause dripping inside the inking system housing. For

applications where web speed is over 400 RPM, remove more

ink from the roll in this process.

2 -Put on the rubber gloves and carefully cut the end of

the bag open and remove the Ink Roll.

Pre-Inked Rolls are intentionally oversaturated to prolong

storage life. There may be a small amount of liquid ink in

the bag when it is opened so be careful handling the

opened bag after the roll is removed. Ink may run out.

FIGURE 14

FIGURE 15

Summary of Contents for WPNP-400NI-PIDS

Page 26: ...26 ...