UniStream

®

PLC

Wiring Guidelines

In order to ensure that the device will operate properly and to avoid electromagnetic

interference:

Use a metal cabinet. Make sure the cabinet and its doors are properly earthed.

Use wires that are properly sized for the load.

Use shielded twisted pair cables for wiring High Speed and Analog I/O signals.

Use shielded cables for wiring thermocouple and RTD signals.

In either case, do not use the cable shield as a signal common / return path.

Route each I/O signal with its own dedicated common wire. Connect common wires

at their respective common (CM) points at the controller.

Individually connect each 0V point and each common (CM) point in the system to the

power supply 0V terminal, unless otherwise specified.

Individually connect each functional ground point ( ) to the earth of the system

(preferably to the metal cabinet chassis).

Use the shortest and thickest wires possible: less than 1m (3.3’) in length, minimum

thickness 14 AWG (2 mm

2

).

Connect the power supply 0V to the earth of the system.

Earthing the cables' shield:

Connect the cable shield to the earth of the system (preferably to the metal cabinet

chassis). Note that the shield must be connected only at one end of the cable; it is

recommended to earth the shield at the PLC-side.

Keep shield connections as short as possible.

Ensure shield continuity when extending shielded cables.

N

OTE

For detailed information, refer to the document System Wiring Guidelines,

located in the Technical Library in the Unitronics’ website.

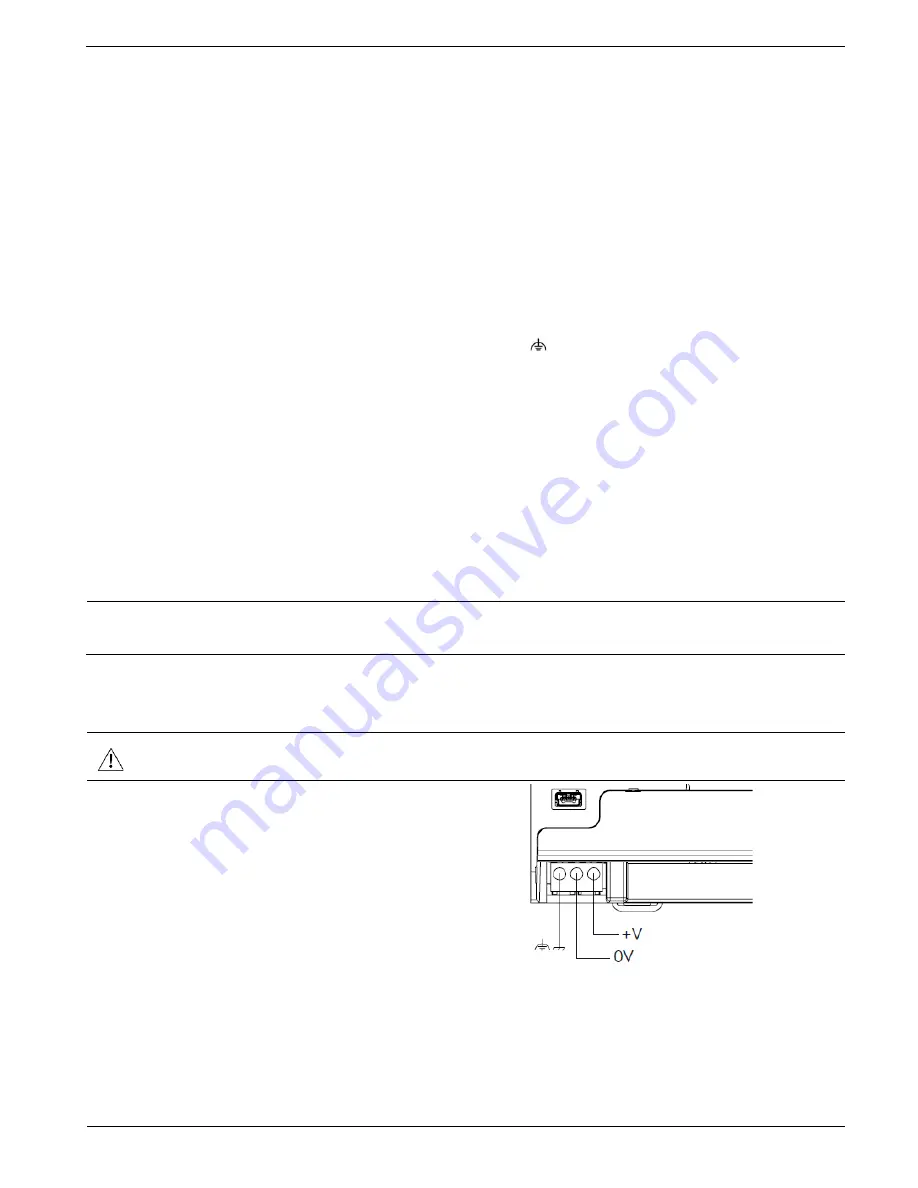

Wiring the Power Supply

The controller requires an external power supply.

In the event of voltage fluctuations or non-conformity to voltage power supply

specifications, connect the device to a regulated power supply.

Connect the +V and 0V terminals as

shown in the accompanying figure.

Connecting Ports

Ethernet

CAT-5e shielded cable with RJ45 connector

USB Device

Use a standard USB cable, Type mini-B

USB Host

Standard USB Type-A plug

8

Unitronics