7

INST

INST

INST

INST

INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

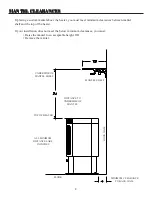

The following formula can be used to determine the maximum

heater rating per the definition of unconfined space:

BTU/HR = (L1+L2) Ft x (W) Ft x (H) Ft x 1000

50

Consider two connecting rooms with an open area between,

with the following dimensions:(See Fig. 2, Example)

L1=15-1/2 Ft., L2=12 Ft., W=12 ft., H=8Ft

50

=52800 BTU/HR

If there were a door between the two rooms the calculation

would be based only on the room with the heater.

BTU/HR=(15-1/2) x (12) x (8) x 1000

50

=29760 BTU/HR

FIGURE 2.

FIGURE 2.

FIGURE 2.

FIGURE 2.

FIGURE 2.

W

W

W

W

When installing the a

hen installing the a

hen installing the a

hen installing the a

hen installing the appliance dir

ppliance dir

ppliance dir

ppliance dir

ppliance directl

ectl

ectl

ectl

ectly on car

y on car

y on car

y on car

y on carpeting

peting

peting

peting

peting,,,,, tile or other comb

tile or other comb

tile or other comb

tile or other comb

tile or other combustib

ustib

ustib

ustib

ustible

le

le

le

le

material, other than wood flooring, the appliance must be installed on a metal or

material, other than wood flooring, the appliance must be installed on a metal or

material, other than wood flooring, the appliance must be installed on a metal or

material, other than wood flooring, the appliance must be installed on a metal or

material, other than wood flooring, the appliance must be installed on a metal or

wood panel extending the full width and depth of the appliance.

wood panel extending the full width and depth of the appliance.

wood panel extending the full width and depth of the appliance.

wood panel extending the full width and depth of the appliance.

wood panel extending the full width and depth of the appliance.

WARNINGWARNINGWARNINGWARNINGWARNING

If the ar

If the ar

If the ar

If the ar

If the area in w

ea in w

ea in w

ea in w

ea in whic

hic

hic

hic

hich the hea

h the hea

h the hea

h the hea

h the heater ma

ter ma

ter ma

ter ma

ter may be oper

y be oper

y be oper

y be oper

y be opera

a

a

a

ated is smaller than tha

ted is smaller than tha

ted is smaller than tha

ted is smaller than tha

ted is smaller than that def

t def

t def

t def

t defined as an

ined as an

ined as an

ined as an

ined as an

unconf

unconf

unconf

unconf

unconfined space or if the b

ined space or if the b

ined space or if the b

ined space or if the b

ined space or if the building is of un

uilding is of un

uilding is of un

uilding is of un

uilding is of unusuall

usuall

usuall

usuall

usually tight constr

y tight constr

y tight constr

y tight constr

y tight construction,

uction,

uction,

uction,

uction, pr

pr

pr

pr

pro

o

o

o

ovide

vide

vide

vide

vide

adequate combustion and ventilation air by one of the methods described in the

adequate combustion and ventilation air by one of the methods described in the

adequate combustion and ventilation air by one of the methods described in the

adequate combustion and ventilation air by one of the methods described in the

adequate combustion and ventilation air by one of the methods described in the

Na

Na

Na

Na

National Fuel Gas Code

tional Fuel Gas Code

tional Fuel Gas Code

tional Fuel Gas Code

tional Fuel Gas Code,,,,, ANSI Z223.1,

ANSI Z223.1,

ANSI Z223.1,

ANSI Z223.1,

ANSI Z223.1, Section 5.3,

Section 5.3,

Section 5.3,

Section 5.3,

Section 5.3, or a

or a

or a

or a

or applica

pplica

pplica

pplica

pplicab

b

b

b

ble local codes.

le local codes.

le local codes.

le local codes.

le local codes.

L2 (12')

L1 (15-1/2')

W (12')

H (8')

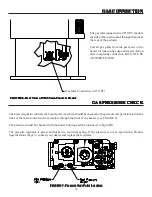

Minimum clearances to combustibles:

Top of heater....................................36"

Sides of heater....................................8"

Front of heater..................................42"

Rear of heater.....................................4"

FIGURE 3. Minimum Clearances

FIGURE 3. Minimum Clearances

FIGURE 3. Minimum Clearances

FIGURE 3. Minimum Clearances

FIGURE 3. Minimum Clearances

36"

8"

8"

4"

42"

Ensur

Ensur

Ensur

Ensur

Ensure the minim

e the minim

e the minim

e the minim

e the minimum c

um c

um c

um c

um clear

lear

lear

lear

learances sho

ances sho

ances sho

ances sho

ances shown in FIGURE 3 ar

wn in FIGURE 3 ar

wn in FIGURE 3 ar

wn in FIGURE 3 ar

wn in FIGURE 3 are maintained f

e maintained f

e maintained f

e maintained f

e maintained for

or

or

or

or

accessibility f

accessibility f

accessibility f

accessibility f

accessibility for pur

or pur

or pur

or pur

or purposes of ser

poses of ser

poses of ser

poses of ser

poses of servicing and pr

vicing and pr

vicing and pr

vicing and pr

vicing and proper oper

oper oper

oper oper

oper oper

oper opera

a

a

a

ation. Left and r

tion. Left and r

tion. Left and r

tion. Left and r

tion. Left and right

ight

ight

ight

ight

c

cc

cclear

lear

lear

lear

learances ar

ances ar

ances ar

ances ar

ances are deter

e deter

e deter

e deter

e determined w

mined w

mined w

mined w

mined when f

hen f

hen f

hen f

hen facing the fr

acing the fr

acing the fr

acing the fr

acing the front of the hea

ont of the hea

ont of the hea

ont of the hea

ont of the heater

ter

ter

ter

ter.....

WARNINGWARNINGWARNINGWARNINGWARNING

WARNINGWARNINGWARNINGWARNINGWARNING

Maintain these clearances to

Maintain these clearances to

Maintain these clearances to

Maintain these clearances to

Maintain these clearances to

ensure adequate space

ensure adequate space

ensure adequate space

ensure adequate space

ensure adequate space

around air opening for

around air opening for

around air opening for

around air opening for

around air opening for

proper operation.

proper operation.

proper operation.

proper operation.

proper operation.