035-19656-003 Rev. A (1004)

4

Unitary Products Group

When the furnace is used in conjunction with a cooling coil, the coil

must be installed parallel with, or in the supply air side of the furnace to

avoid condensation in the primary heat exchanger. When a parallel flow

arrangement is used, dampers or other means used to control airflow

must be adequate to prevent chilled air from entering the furnace. If

manually operated, the damper must be equipped with means to pre-

vent the furnace or the air conditioner from operating unless the damper

is in full heat or cool position.

DUCTWORK INSTALLATION AND SUPPLY PLENUM

CONNECTION

Attach the supply plenum to the furnace outlet duct connec-

tion flanges. This is typically through the use of S cleat

material when a metal plenum is used. The use of an

approved flexible duct connector is recommended on all

installations. This connection should be sealed to prevent

air leakage. The sheet metal should be crosshatched to

eliminate any popping of the sheet metal when the indoor

fan is energized.

When replacing an existing furnace, if the existing plenum is not the

same size as the new furnace then the existing plenum must be

removed and a new plenum installed that is the proper size for the new

furnace. If the plenum is shorter than 12” (30.5 cm) the turbulent air flow

may cause the limit controls not to operate as designed, or the limit con-

trols may not operate at all.

The duct system is a very important part of the installation.

If the duct

system is improperly sized the furnace will not operate properly.

The ducts attached to the furnace plenum, should be of sufficient size

so that the furnace operates at the specified external static pressure

and within the air temperature rise specified on the nameplate.

Table 2 is a guide for determining whether the rectangular duct system

that the furnace is being connected to be of sufficient size for proper fur-

nace operation.

Use the Example below to help you in calculating the duct area to deter-

mine whether the ducts have sufficient area so that the furnace oper-

ates at the specified external static pressure and within the air

temperature rise specified on the nameplate.

Ex. The furnace input is 80,000 BTUH and 1,200 CFM. The recom-

mended duct area is 280 sq.in, there are two 8 x 14 rectangular ducts

attached to the plenum and there are two 7 inch round ducts attached to

the furnace.

1.

Take 8 x 14, which equals 112 sq.in. X 2, which equals 224 square

inch then go to round duct size located in Table 3.

2.

The square inch area for 7 inch round pipe is 38.4, multiply by 2 for

two round ducts which equals 76.8 square inch,

3.

Then take the 224 square inch from the rectangular duct and add it

to the 76.8 sq.in. of round duct. The total square inch of duct

attached to the furnace plenum is 300.8 square inch. This exceeds

the recommended 280 square inch of duct.

In this example, the duct system attached to the plenum has a sufficient

area so that the furnace operates at the specified external static pres-

sure and within the air temperature rise specified on the nameplate.

1.

The Air Temperature Rise is determined by subtracting the Return

Air Temperature Reading from the Supply Air Temperature Read-

ing.

2.

The External Static Pressure is determined by adding the Supply

Duct Static Pressure reading to the Return Duct Static Pressure

reading, adding the pressure across any applied a-coil and the

drop across the return air filter.

The cooling coil must be installed in the supply air duct, down-

stream of the furnace. Cooled air may not be passed over the heat

exchanger.

The duct system must be properly sized to obtain the correct airflow

for the furnace size that is being installed.

Refer to Table 8 and the furnace rating plate for the correct rise

range and static pressures

If the ducts are undersized, the result will be high duct static pres-

sures and/or high temperature rises which can result in a heat

exchanger OVERHEATING CONDITION. This condition can result

in premature heat exchanger failure, which can result in personal

injury, property damage, or death.

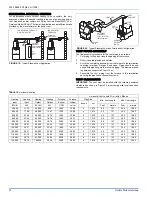

TABLE 2:

Minimum Duct Sizing For Proper Airflow

Input

Airflow

Return

1

Rectangular

2

Round

2

Supply

3

BTU/H(kW)

CFM(m³)

In² (cm²)

in. x in.(cm x cm)

in. (cm) dia.

In²(cm²)

40,000(11.72)

1,200(33.98)

280 (711)

14 x 20 (35.6 x 50.8)

18 (45.7)

216 (549)

60,000 (17.58)

1,200 (33.98)

280 (711)

14 x 20 (35.6 x 50.8)

18 (45.7)

216 (549)

80,000 (23.44)

1,200 (33.98)

280 (711)

14 x 20 (35.6 x 50.8)

18 (45.7)

216 (549)

80,000 (23.44)

1,600 (45.31)

360 (914)

18 x 20 (45.7 x 50.8)

22 (55.8)

280 (711)

80,000 (23.44)

2,000 (56.63)

440 (1,118)

20 x 22 (50.8 x 55.8)

24 (60.9)

390 (991)

100,000 (29.31)

1,200 (33.98)

320 (813)

16 x 20 (40.6 x 50.8)

20 (50.8)

336 (853)

100,000 (29.31)

1,600 (45.31)

360 (914)

18 x 20 (45.7 x 50.8)

22 (55.8))

280 (711)

100,000 (29.31)

2,000 (56.63)

440 (1,118)

20 x 22 (50.8 x 55.8)

24 (60.9)

390 (991)

115,000 (35.17)

1,600 (45.31)

360 (914)

18 x 20 (45.7 x 50.8)

22 (55.8))

280 (711)

115,000 (35.17)

2,000 (56.63)

440 (1,118)

20 x 22 (50.8 x 55.8)

24 (60.9)

390 (991)

130,000 (41.03)

2,000 (56.63)

440 (1,118)

20 x 22 (50.8 x 55.8)

24 (60.9)

390 (991)

NOTE: This chart does not replace proper duct sizing calculations or take into account static pressure drop for run length and fittings. Watch out for the temperature rise and static pressures.

1.

Maximum return air velocity in rigid duct @ 700 feet per minute (19.82 m

3

/ minute).

2.

Example return main trunk duct minimum dimensions.

3.

Maximum supply air velocity in rigid duct @ 900 feet per minute (25.49 m

3

/ minute).

TABLE 3:

Round Duct Size

Round Duct Size

Calculated Area For Each Round Duct Size

inches (cm)

Sq.in (cm

2

)

5 (13)

19.6 (126)

6 (15)

28.2 (182)

7 (18)

38.4 (248)

8 (20)

50.2 (324)

9 (23)

63.6 (410)

10 (25)

78.5 (506)

11 (28)

95 (613)

12 (30)

113.1 (730)

13 (33)

132.7 (856)

14 (36)

153.9 (993)