035-19656-003 Rev. A (1004)

22

Unitary Products Group

ADJUSTMENT OF TEMPERATURE RISE

The temperature rise, or temperature difference between the return air

and the heated supply air from the furnace, must be within the range

shown on the furnace rating plate and within the application limitations

as shown in Table 8.

After about 20 minutes of operation, determine the furnace temperature

rise. Take readings of both the return air and the heated air in the ducts,

about six feet (1.83 m) from the furnace where they will not be affected

by radiant heat. Increase the blower speed to decrease the temperature

rise; decrease the blower speed to increase the rise.

All direct-drive blowers have multi-speed motors. The blower motor

speed taps are located in the control box in the blower compartment.

Refer to Figure 33, and the unit-wiring label to change the blower

speed. To use the same speed tap for heating and cooling, the heat ter-

minal and cool terminal must be connected using a jumper wire and

connected to the desired motor lead. Place all unused motor leads on

Park terminals. Two are provided.

ADJUSTMENT OF FAN CONTROL SETTINGS

This furnace is equipped with a time-on/time-off heating fan control. The

fan on delay is fixed at 30 seconds. The fan off delay has 4 settings (60,

90, 120 and 180 seconds). The fan off delay is factory set to 120 sec-

onds. The fan-off setting must be long enough to adequately cool the

furnace, but not so long that cold air is blown into the heated space. The

fan-off timing may be adjusted by positioning the jumper on two of the

four pins as shown in Figure 33.

The furnace control board also allows user selection of the blower

speed that is energized during continuous fan operation. Place jumper

on the HI COOL, LO COOL, or HEAT pins.

FILTER PERFORMANCE

The airflow capacity data published in Table 17 represents blower per-

formance WITHOUT filters. To determine the approximate blower per-

formance of the system, apply the filter drop value for the filter being

used or select an appropriate value from the Table 16.

The filter pressure drop values in Table 16 are typical values for the

type of filter listed and should only be used as a guideline. Actual pres-

sure drop ratings for each filter type vary between filter manufacturers.

* Washable Fibers are the type supplied with furnace (if supplied).

APPLYING FILTER PRESSURE DROP TO

DETERMINE SYSTEM AIRFLOW

To determine the approximate airflow of the unit with a filter in place, fol-

low the steps below:

1.

Select the filter type.

2.

Select the number of return air openings or calculate the return

opening size in square inches to determine the proper filter pres-

sure drop.

3.

Determine the External System Static Pressure (ESP) without the

filter.

4.

Select a filter pressure drop from the table based upon the number

of return air openings or return air opening size and add to the

ESP from Step 3 to determine the total system static.

5.

If total system static matches a ESP value in the airflow table (i.e.

0.20 w.c. (50 Pa), 0.60 w.c. (150 Pa), etc,) the system airflow cor-

responds to the intersection of the ESP column and Model/Blower

Speed row.

6.

If the total system static falls between ESP values in the table (i.e.

0.58 w.c. (144 Pa), 0.75 w.c. (187 Pa), etc.), the static pressure

may be rounded to the nearest value in the table determining the

airflow using Step 5 or calculate the airflow by using the following

example.

The temperature rise, or temperature difference between the return

air and the supply (heated) air from the furnace, must be within the

range shown on the furnace rating plate and within the application

limitations shown in Table 8 “ELECTRICAL AND PERFORMANCE

DATA”.

The supply air temperature cannot exceed the “Maximum Supply

Air Temperature” specified in these instructions and on the fur-

nace rating plate. Under NO circumstances can the furnace be

allowed to operate above the Maximum Supply Air Temperature.

Operating the furnace above the Maximum Supply Air Temperature

will cause premature heat exchanger failure, high levels of Carbon

Monoxide, a fire hazard, personal injury, property damage, and/or

death.

Do not energize more than one motor speed at a time or damage to

the motor will result.

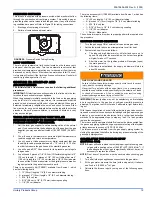

FIGURE 31:

Typical Heat/Cool Speed Tap Connections

RED - LOW SPEED

YELLOW - MED. LOW SPEED

BLACK - HIGH SPEED

BLUE -MED. HIGH SPEED

NEUTRALS

HI

COOL

HEA

T

EAC

L1

XFMR

HUM

P

ARK

P

ARK

LO

COOL

Y1 Y/Y2 W

R

G

C

FAN OFF

ADJUSTMENT

JUMPER

CONTINUOUS

FAN SPEED

JUMPER

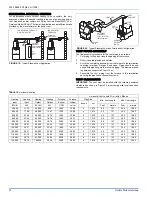

TABLE 16:

Filter Performance - Pressure Drop Inches W.C. and (kPa)

Airflow Range

Minimum Opening Size

Filter Type

Disposable Washable

Fibers* Pleated

1 Opening

2 Openings

1 Opening

2 Openings

1 Opening

2 Openings

1 Opening

2 Openings

CFM

Cm/m

In³

m³

In³

m³

inwc

kPa

inwc

kPa

inwc

kPa

inwc

kPa

inwc

kPa

inwc

kPa

0 - 750

0 - 21.24

230 0.0038

0.01 0.0025

0.01 0.0025

0.15 0.0374

751 - 1000

21.27 - 28.32

330 0.0054

0.05 0.0125

0.05 0.0125

0.2

0.0498

1001 - 1250

28.35 - 35.40

330 0.0054

0.1

0.0249

0.1

0.0249

0.2

0.0498

1251 - 1500

35.42 - 42.47

330 0.0054

0.1

0.0249

0.1

0.0249

0.25 0.0623

1501 - 1750

42.50 - 49.55

380 0.0062 658 0.0108 0.15 0.0374 0.09 0.0224 0.14 0.0349 0.08 0.0199

0.3

0.0747 0.17 0.0423

1751 - 2000

49.58 - 56.63

380 0.0062 658 0.0108 0.19 0.0473 0.11 0.0274 0.18 0.0448

0.1

0.0249

0.3

0.0747 0.17 0.0423

2001 & Above 56.66 & Above 463 0.0076 658 0.0108 0.19 0.0473 0.11 0.0274 0.18 0.0448

0.1

0.0249

0.3

0.0747 0.17 0.0423