268894-UIM-A-0407

14

Unitary Products Group

SECTION VII: VENT SYSTEM

VENT SAFETY

This Category I, furnace is designed for residential application. It may

be installed without modification in a basement, garage, equipment

room, alcove, attic or any other indoor location where all required clear-

ance to combustibles and other restrictions are met.

CATEGORY 1 - 450 F. MAX. VENT TEMP.

The venting system must be installed in accordance with Section 5.3,

Air for Combustion and Ventilation, of the National Fuel Gas Code

Z223.1/NFPA 54 (latest edition), or Sections 7.2, 7.3 or 7.4 of CSA

B149.1, National Gas and Propane Codes (latest edition) or applicable

provisions of the local building code and these instructions.

The furnace shall be connected to any type of B, BW or L vent connec-

tor, and shall be connected to a factory-built or masonry chimney.

The

furnace shall not be connected to a chimney flue serving a sepa-

rate appliance designed to burn solid fuel.

The furnace rating plate lists the maximum vent gas temperature. This

temperature must be used to select the appropriate venting materials

and clearances.

It is recommended that the appliance is installed in a location where the

space temperature is 32 °F (0°C) or higher. If the appliance is installed

in a location where the ambient temperature is below 32 °F (0°C), the

combustion by-products could condense causing damage to the appli-

ance heat exchanger.

IMPORTANT:

The “VENT SYSTEM” must be installed as specified in

these instructions for Residential and Modular Homes.

This appliance may be common vented with another gas appliance for

residential installations as allowed by the codes and standards listed in

these instructions.

Approved Modular Homes must be vented with an approved roof jack

and may not be common vented with other appliances.

VENTING

Category I venting consists of vertically venting one or more appliances

in B-vent or masonry chimney (as allowed), using single wall metal pipe

or B-vent connectors. Type B-vent system extends in a general vertical

direction and does not contain offsets exceeding 45 degrees. A vent

system having not more than one 60 degree offset is permitted.

The vent system must be attached to the flue collar with a minimum of

two (2) mechanical fasteners, such as screws or rivets. See Figure 20.

VENTING INTO AN EXISTING CHIMNEY

For Category I installations, the furnace shall be connected to a factory

built chimney or vent complying with a recognized standard, or a

masonry or concrete chimney lined with a material acceptable to the

authority having jurisdiction. Venting into an unlined masonry chimney

or concrete chimney is prohibited.

Whenever possible, B-1 metal pipe should be used for venting. Where

use of an existing chimney is unavoidable, the following rules must be

followed:

1.

The masonry chimney must be built and installed in accordance

with nationally recognized building codes or standards and must

be lined with approved fire clay tile flue liners or other approved

liner material that will resist corrosion, softening, or cracking from

flue gases.

THIS FURNACE IS NOT TO BE VENTED INTO AN

UNLINED MASONRY CHIMNEY.

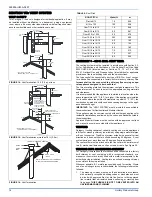

FIGURE 14:

Vent Termination 10 ft. (3.0 m) or less

FIGURE 15:

Vent Termination more than 10 ft. (3.0 m)

FIGURE 16:

Vent Termination

WALL OR

PARAPET

RIDGE

CHIMNEY

CHIMNEY

3 FT (0.9 m)

MIN.

2 FT (0.6 m)

MIN.

10 FT (3.0 m) OR LESS

FROM RIDGE, WALL, OR PARAPET

*

*

2 FT (0.6 m)

MIN.

3 FT (0.9 m)

MIN.

CHIMNEY

2 FT (0.6 m)

MIN.

10 FT (3.0 m)

OR LESS

*

10 FT (3.0 m)

OR LESS

MORE THAN

10 FT (3.0 m)

3 FT (0.9 m)

MIN.

WALL OR

PARAPET

RIDGE

CHIMNEY

CHIMNEY

3 FT (0.9 m)

MIN.

2 FT (0.6 m)

MIN.

MORE THAN

10 FT (3.0 m)

NOTE:

NO

HEIGHT ABOVE

PARAPET REQUIRED

WHEN DISTANCE

FROM WALLS OR

PARAPET IS MORE

THAN 10 FT (3.0 m).

10 FT

(3.0 m)

HEIGHT ABOVE ANY

ROOF SURFACE WITHIN

10 FT (3.0 m) HORIZONTALLY

MORE THAN 10 FT (3.0 m)

FROM RIDGE, WALL, OR PARAPET

*

*

*

LOWEST DISCHARGE OPENING

LISTED CAP

LISTED GAS

VENT

H (min) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

12

X

ROOF PITCH

IS X/12

TABLE 8:

Roof Pitch

ROOF PITCH

H(min) ft

m

Flat to 6/12

1.0

0.30

6/12 to 7/12

1.25

0.38

Over 7/12 to 8/12

1.5

0.46

Over 8/12 to 9/12

2.0

0.61

Over 9/12 to 10/12

2.5

0.76

Over 10/12 to 11/12

3.25

0.99

Over 11/12 to 12/12

4.0

1.22

Over 12/12 to 14/12

5.0

1.52

Over 14/12 to 16/12

6.0

1.83

Over 16/12 to 18/12

7.0

2.13

Over 18/12 to 20/12

7.5

2.27

Over 20/12 to 21/12

8.0

2.44