26

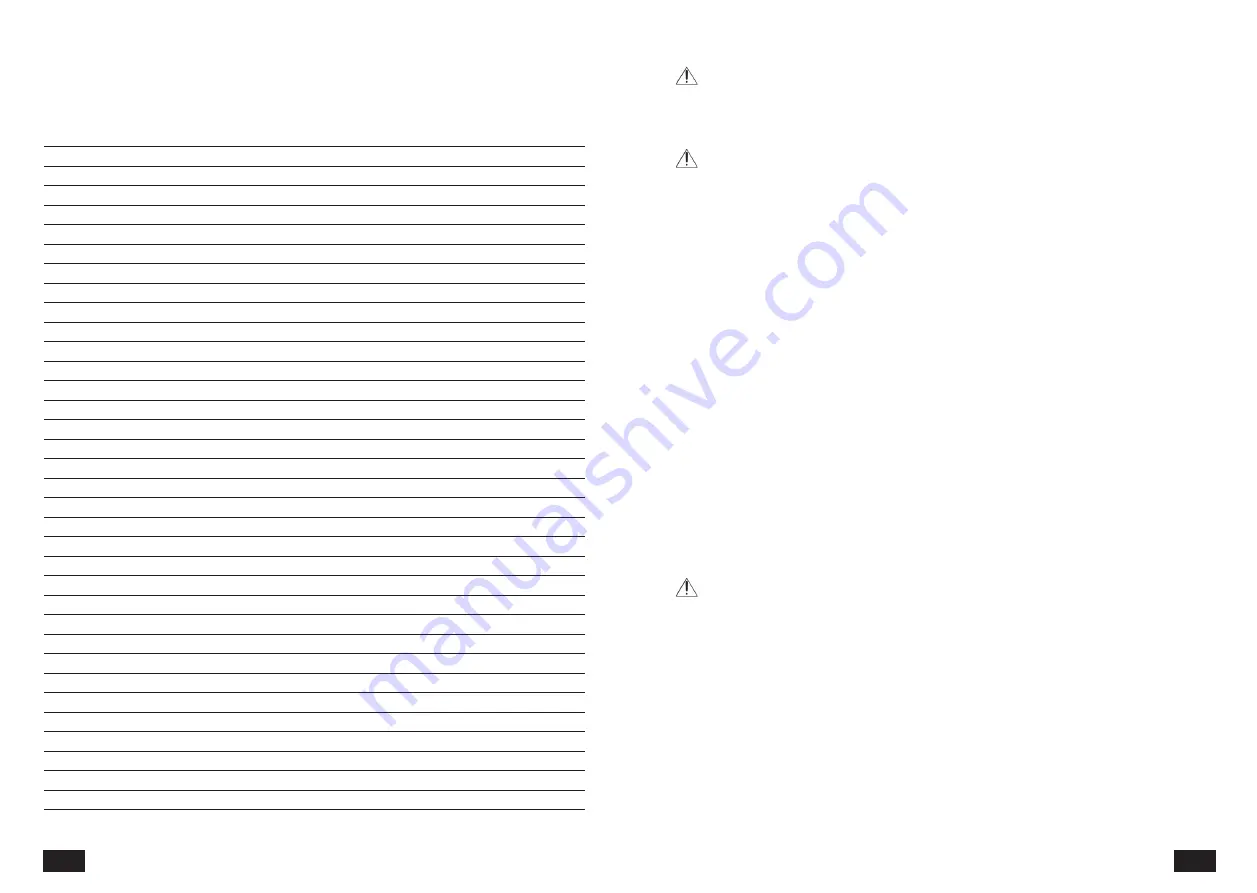

Drilling/milling head

Position

Dimensions

Name

1

35 GB894.1-86

Outer safety ring

2

207 GB276-89

Cylindrical bearing

3

AT320-09-020

Shaft socket

4

AT320-09-021A

Toothed gear

5

50207 GB277-89

Radial ball bearing

6

72 JB/GQ0251-89

Bearing socket

7

35 GB894.1-86

Outer safety ring

8

AT320-09-018

Levelling ledge

9

8×45 GB1097-79

Flat spline

10

M3×8 GB67-85

Round head setting screw

11

M4×8 GB68-85

Sink head screws with groove

12

M30×1.5 GB812-88

Round nut

13

2007106 GB297-84

Conical bearing

14

AT320-09-008A

Spindle socket

15

D2007107 GB297-84

Conical bearing

16

AT320-09-022

T - wedge

17

AT320-09-009A

Drilling/milling spindle

18

45 JB/GQ0324-89

Felt ring

19

M4×12 GB71-85

Setting screws with conical tip

20

AT320-09-013

Bearing cover

21

AT320-09-034

Handle housing

22

1×7×12 GB2089-80

Spring

23

AT320-09-035

Connecting screw

24

5×50 GB117-86

Conical stud

25

AT320-09-044

Positioning handle

26

BM8×40 GB4141.14-84

Long socket round grip

27

M4×8 GB67-85

Round head setting screw

28

5×45 GB119-86

Cylindrical stud

29

AT320-09-036

Positioning plate

30

M5×16 GB70-76

Screws with inner hexagonal head slot

31

4×20 GB117-86

Conical stud

32

AT320-09-042

Left transmission cover

33

AT320-09-040

Shifting fork shaft

34

AT320-09-038

Swivelling gate

7

Milling

•

Make sure the material is fed to the machine in the correct direction that is, against the directions of the

spinning cutting head.

Lathe turning operations

•

Do not allow unauthorized persons to stand close to your machine to prevent injuries by spinning work

piece.

•

Make sure that the operating person wears personal protection gear to prevent injuries from flying and

spinning metal cuts and sawdust.

•

Do not carry objects in your upper pocket. Do not wear jewellery. Always place tools and measuring

equipment on the same place.

•

The operating personnel must wear working cloth and must not wear gloves. Long hair must be tied

behind your head to prevent injuries by spinning parts.

•

Stairs for the operating personnel must be equipped with skid-proof surface. Always keep secure and

stable position during work. Do not lean over and above the machine. Do not overreach.

•

Do not work with work pieces that do not comply with the dimensioning requirements and with the

machine specifications.

•

Make sure that the work piece and the cutting tools are securely fastened. After you have fastened

the cutting tool, make sure to remove all wrenches and other fastening tools from the spindle or chuck.

Before starting the machine, make sure the operating personnel always removes all wrenches,

screwdrivers and other fastening tools from the machine.

•

Make sure to choose and use correct tools. Work piece must be always securely fastened. Do not touch

the work piece.

•

Perform maintenance, adjustment or tool changing only if the machine is switched off and the spindle has

completely stopped.

•

Never leave the running machine unattended. You may leave the machine only if it is switched off and the

chuck or spindle came to a complete stop.

•

Also beware of other risks and dangerous situations that my occur during operation.

Power equipment

•

If your machine is equipped with depressed springs, use suitable device to release them slowly and

safely.

Summary of Contents for AT320

Page 12: ...12 21 Drilling milling head...