32

unigreen

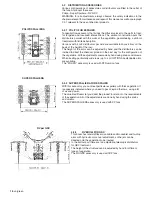

TAB. 3

TABLE OF DELIVERY OF NOZZLES FOR ATOMISERS

TABLE 4-5 TABLES OF DELIVERY OF NOZZLES FOR HAND LANCES

TABLE OF DELIVERY IN LITRES / MIN. OF THE CONICAL NOZZLES FOR MITRA SPRAY GUN

note: standard Ø2,5 nozzle

DIAMETER NOZZLE

Ø 1,0

Ø 1,2

Ø 1,5

Ø 1,8

Ø 2,0

Ø 2,3

Ø 2,5

Ø 3,0

PRESSURE (BAR)

JET

CAPACITY ( Lt / min )

15

cone

2,45

3,60

4,60

5,90

6,90

8,10

9,20

11,5

direct jet

2,50

3,80

5,10

7,30

8,80

10,8

13,0

18,4

25

cone

3,00

4,25

5,70

7,20

8,10

10,2

11,4

14,4

direct jet

3,10

4,60

6,50

9,30

11,7

14,1

16,4

24,1

35

cone

3,40

4,70

6,60

8,50

10,2

12,9

14,0

18,0

direct jet

3,50

5,40

7,40

10,8

13,4

16,8

19,1

28,2

40

cone

3,55

5,20

6,90

9,20

10,9

13,7

14,5

18,8

direct jet

3,65

5,90

7,80

11,7

14,3

17,9

21,0

30,1

50

cone

4,00

5,60

7,70

10,5

12,5

14,9

16,4

20,9

direct jet

4,10

6,30

8,60

12,7

15,8

19,7

23,0

33,0

TABLE. 5

TABLE OF DELIVERY IN LITRES / MIN. OF THE CONICAL NOZZLES FOR LEVER LANCE

note: standard Ø1,5 nozzle

DIAMETER NOZZLE

Ø 1,0

Ø 1,2

Ø 1,5

Ø 1,75

Ø 2,0

Ø 2,2

Ø 2,5

PRESSURE (BAR)

JET

CAPACITY ( Lt / min )

5

cone

1,16

1,40

1,90

2,25

2,65

2,90

3,50

direct jet

1,40

1,70

2,50

3,95

4,7

6,00

7,70

8

cone

1,40

1,80

2,60

2,80

3,40

3,65

4,45

direct jet

1,70

2,20

3,40

4,85

6,00

7,60

9,80

10

cone

1,50

1,96

2,90

3,10

3,90

4,10

5,00

direct jet

1,90

2,40

3,75

5,40

6,95

8,55

11,0

15

cone

1,88

2,40

3,40

3,80

4,50

5,00

6,10

direct jet

2,30

3,00

4,50

6,65

8,30

10,4

13,4

30

cone

2,60

3,40

4,80

5,40

6,30

7,10

8,70

direct jet

3,20

4,20

6,40

9,40

11,7

14,7

19,1

50

cone

3,40

4,40

6,20

6,80

8,10

9,20

11,2

direct jet

4,10

5,40

8,30

11,8

15,1

19,1

24,6

TABLE. 4

TABLE OF DELIVERY IN LITRES / MIN.

LOW VOLUME TR CONICAL NOZZLES FOR ATOMISER

NOZZLE TR80 ISO

LILLAC

OLIVE

ORANGE

GREEM

YELLOW DARK BLUE

RED

BROWN

005

0067

01

015

02

03

04

05

PRESSURE

5 bar

0,25

0,35

0,51

0,76

1,03

1,53

2,04

2,55

7 bar

0,30

0,41

0,60

0,90

1,22

1,81

2,41

3,01

10 bar

0,36

0,49

0,72

1,07

1,45

2,17

2,88

3,60

12 bar

0,39

0,54

0,78

1,18

1,60

2,38

3,16

3,94

15 bar

0,44

0,60

0,88

1,31

1,79

2,66

3,53

4,41

18 bar

0,48

0,66

0,96

1,44

1,96

2,91

3,87

4,82

20 bar

0,51

0,70

1,01

1,52

2,07

3,07

4,08

5,09

Code : 3400/0577F 3400/0578F 3400/0579F 3400/0580F 3400/0581F 3400/0583F 3400/0584F 3400/0585F

TAB. 3

ISO

Summary of Contents for TurboTeuton P500

Page 35: ...unigreen 35...