28

unigreen

unigreen spa

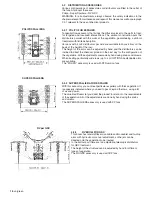

Tabella erogazione in Litri/ettaro Turbo Teuton 20 getti

Lt./ha spreading rate table for Turbo Teuton 20 NOZZLES

ISO OLIVA -Olive

ISO ARANCIO -Orange

Larghezza di lavoro

PRESSIONE bar

5

7

10

12

15

18

20

5

7

10

12

15

18

20

working width

3,5

667 781 933 1029 1143 1257 1333 971 1143 1371 1486 1676 1829 1924

4

583 683 817 900 1000 1100 1167 850 1000 1200 1300 1467 1600 1683

5

467 547 653 720 800 880 933 680 800 960 1040 1173 1280 1347

1,8

6

389 456 544 600 667 733 778 567 667 800 867 978 1067 1122

7

333 390 467 514 571 629 667 486 571 686 743 838 914 962

1,8 m.

3,5

600 703 840 926 1029 1131 1200 874 1029 1234 1337 1509 1646 1731

4

525 615 735 810 900 990 1050 765 900 1080 1170 1320 1440 1515

5

420 492 588 648 720 792 840 612 720 864 936 1056 1152 1212

2

6

350 410 490 540 600 660 700 510 600 720 780 880 960 1010

7

300 351 420 463 514 566 600 437 514 617 669 754 823 866

2 m.

3,5

480 562 672 741 823 905 960 699 823 987 1070 1207 1317 1385

4

420 492 588 648 720 792 840 612 720 864 936 1056 1152 1212

5

336 394 470 518 576 634 672 490 576 691 749 845 922 970

2,5

6

280 328 392 432 480 528 560 408 480 576 624 704 768 808

7

240 281 336 370 411 453 480 350 411 494 535 603 658 693

2,5 m.

Litri/min.

7,0

8,2

9,8

10,8 12,0 13,2 14,0 10,2 12,0 14,4 15,6 17,6 19,2 20,2

Tab. 3215/0000F

ug. sing.

0,35 0,41 0,49 0,54 0,60 0,66 0,70 0,51

0,6 0,72 0,78 0,88 0,96 1,01

ISO 20 GETTI

Ve

lo

c

ità

Km

/h

s

p

eed

Litri/ha

Veloc

ità Km/h

s

p

eed

Ve

lo

c

ità

Km

/h

s

p

eed

Litri/ha

Litri/ha

unigreen spa

Tabella erogazione in Litri/ettaro Turbo Teuton 10 getti

Lt./ha spreading rate table for Turbo Teuton 10 NOZZLES

ISO ARANCIO -Orange

ISO GIALLO -Yellow

Larghezza di lavoro

PRESSIONE bar

5

7

10

12

15

18

20

5

7

10

12

15

18

20

working width

3,5

486 571 686 743 838 914 962 962 1133 1352 1486 1657 1810 1914

4

425 500 600 650 733 800 842 842 992 1183 1300 1450 1583 1675

5

340 400 480 520 587 640 673 673 793 947 1040 1160 1267 1340

1,8

6

283 333 400 433 489 533 561 561 661 789 867 967 1056 1117

7

243 286 343 371 419 457 481 481 567 676 743 829 905 957

1,8 m.

3,5

437 514 617 669 754 823 866 866 1020 1217 1337 1491 1629 1723

4

383 450 540 585 660 720 758 758 893 1065 1170 1305 1425 1508

5

306 360 432 468 528 576 606 606 714 852 936 1044 1140 1206

2

6

255 300 360 390 440 480 505 505 595 710 780 870 950 1005

7

219 257 309 334 377 411 433 433 510 609 669 746 814 861

2 m.

3,5

350 411 494 535 603 658 693 693 816 974 1070 1193 1303 1378

4

306 360 432 468 528 576 606 606 714 852 936 1044 1140 1206

5

245 288 346 374 422 461 485 485 571 682 749 835 912 965

2,5

6

204 240 288 312 352 384 404 404 476 568 624 696 760 804

7

175 206 247 267 302 329 346 346 408 487 535 597 651 689

2,5 m.

Litri/min.

5,1

6,0

7,2

7,8

8,8

9,6

10,1 10,1 11,9 14,2 15,6 17,4 19,0 20,1

Tab. 3215/0000F

ug. sing.

0,51

0,6 0,72 0,78 0,88 0,96 1,01 1,01 1,19 1,42 1,56 1,74

1,9 2,01

Veloc

ità Km/h

s

p

eed

Litri/ha

Ve

lo

c

ità

Km

/h

s

p

eed

Ve

lo

c

ità

Km

/h

s

p

eed

Litri/ha

Litri/ha

ISO 10 GETTI

N.B. to calculate the different ranges it is sufficient to multiply the value lt/hectare by the corresponding width

indicated in the table and divide it by the new width (see chapter 6.3, page 21).

TABLES FOR CALIBRATING POLIPO 5+5 (10 NOZZLES) NARROW ROWS

TurboTeuton CALIBRATING TABLES

TABLES FOR CALIBRATING POLIPO 5+5 (20 NOZZLES) NARROW ROWS

Summary of Contents for TurboTeuton P500

Page 35: ...unigreen 35...