C.I.B. UNIGAS

- M039213CB

34

Oil Flow Rate Settings by means of Berger STM30../Siemens SQM40.. actuator

1

Once the air and gas flow rates are adjusted, turn the burner off, switch it on again by turning the

CM

switch to the oil operation

(OIL, on the burner control panel (see page 38).

2

with the electrical panel open, prime the oil pump acting directly on the related

CP

contactor (see next picture): check the pump

motor rotation and keep pressing for some seconds until the oil circuit is charged;

3

bleed the air from the

M

pressure gauge port (Fig. 22) by loosing the cap without removing it, then release the contactor.

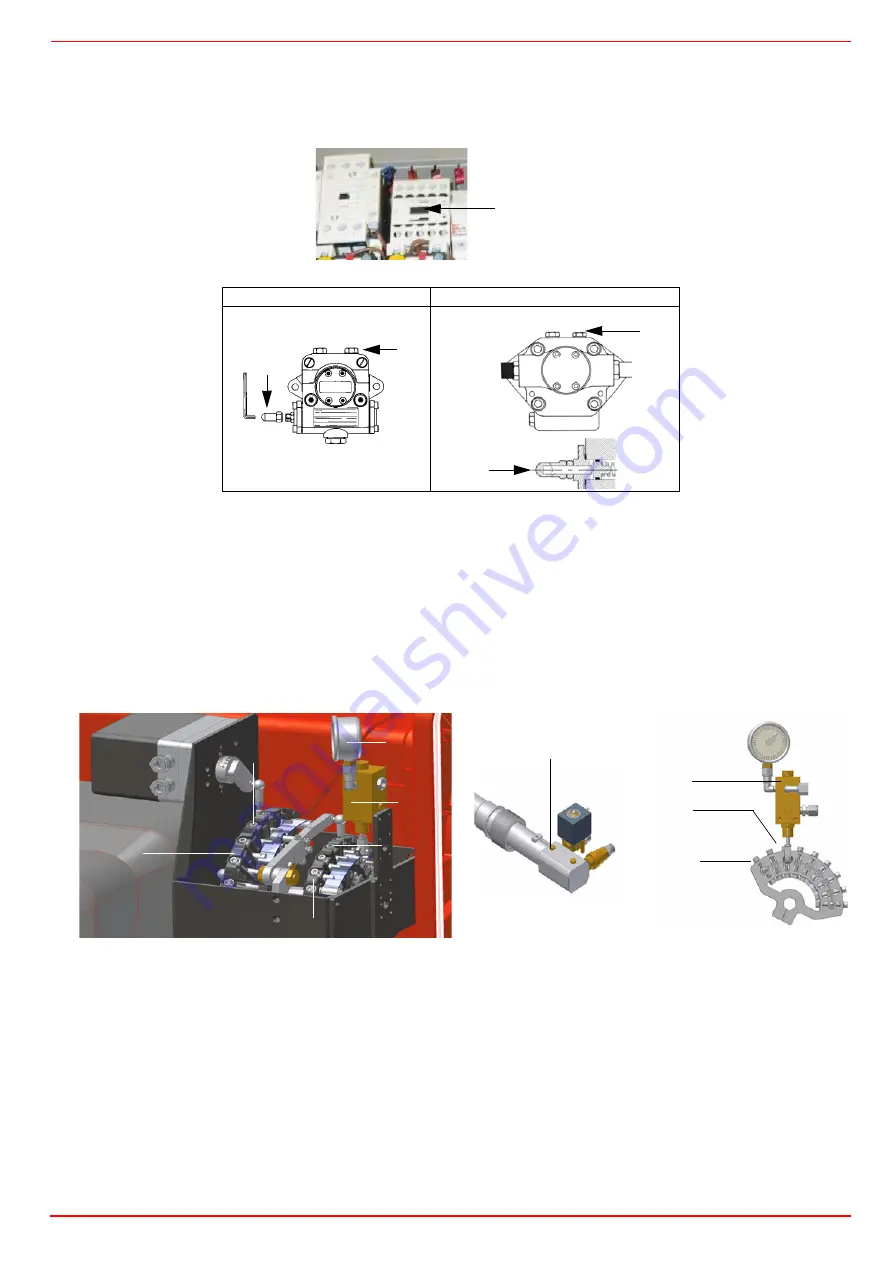

Fig. 22

4

Before starting the burner up, drive the high flame actuator microswitch matching the low flame one (in order to let the burner ope-

rates at the lowest output) to achieve safely the high flame stage .

5

record the high flame value set during the gas operation adjustments (see previous paragraphs);

6

start the burner up by means of the thermostat series and wait until the pre-purge time comes to an end and that the bruner starts

up;

7

drive the burner to high flame stage, by means fo the thermostat

TAB

(high/low flame thermostat - see Wiring diagrams), as far as

fully-modulating burners, see related paragraph.

8

Then move progressively the microswitch to higher values until it reaches the high flame position; always check the combustion

values and eventually adjusting the oil pressure (see next step).

9

the nozzle supply pressure is already factory-set and must not be changed. Only if necessary, adjust the supply pressure as fol-

lows (see related paragraph);insert a pressure gauge into the port shown on Fig. 22 and act on on the pump adjusting screw

VR

(see Fig. 22 and page 22) as to get the nozzle pressure at 25bar (Fluidics nozzles - see page 33).

10 in order to get the maximum oil flow rate, adjust the pressure (reading its value on the

PG

pressure gauge) without changing the air

flow rate set during the gas operation adjustments (see previous paragraph): checking always the combustion parameters, the

adjustment is to be performed by means of the

SV2

adjusting cam screw (see picture) when the cam has reached the high flame

position.

11 as for the point-to-point regulation in order to set the cam foil shape, move the oil low flame microswitch a little lower than the maxi-

mum position (90°);

12 set the

TAB

thermostat to the minimum(as far as fully-modulating burners, see related paragraph) in order that the actuator moves

progressively towards the low flame position;

13 move the low flame cam towards the minimum to move the actuator towards the low flame until the two bearings find the adjusting

screw that refers to a lower position: screw

V2

to increase the rate, unscrew to decrease, in order to get the pressure as showed

on chart/diagram on “Adjusting light oil flow rate” on page 33, according to the requested rate.

Suntec TA..

Suntec T..

Fig. 23

Fig. 24

CP

VR

M

M

VR

SV1

V1

SV2

RP

PG

SC

V2

Pressure gauge port

RP

PG

V2

SV2

Summary of Contents for HR93A

Page 45: ...C I B UNIGAS M039213CB 45...