31

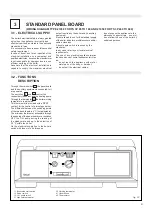

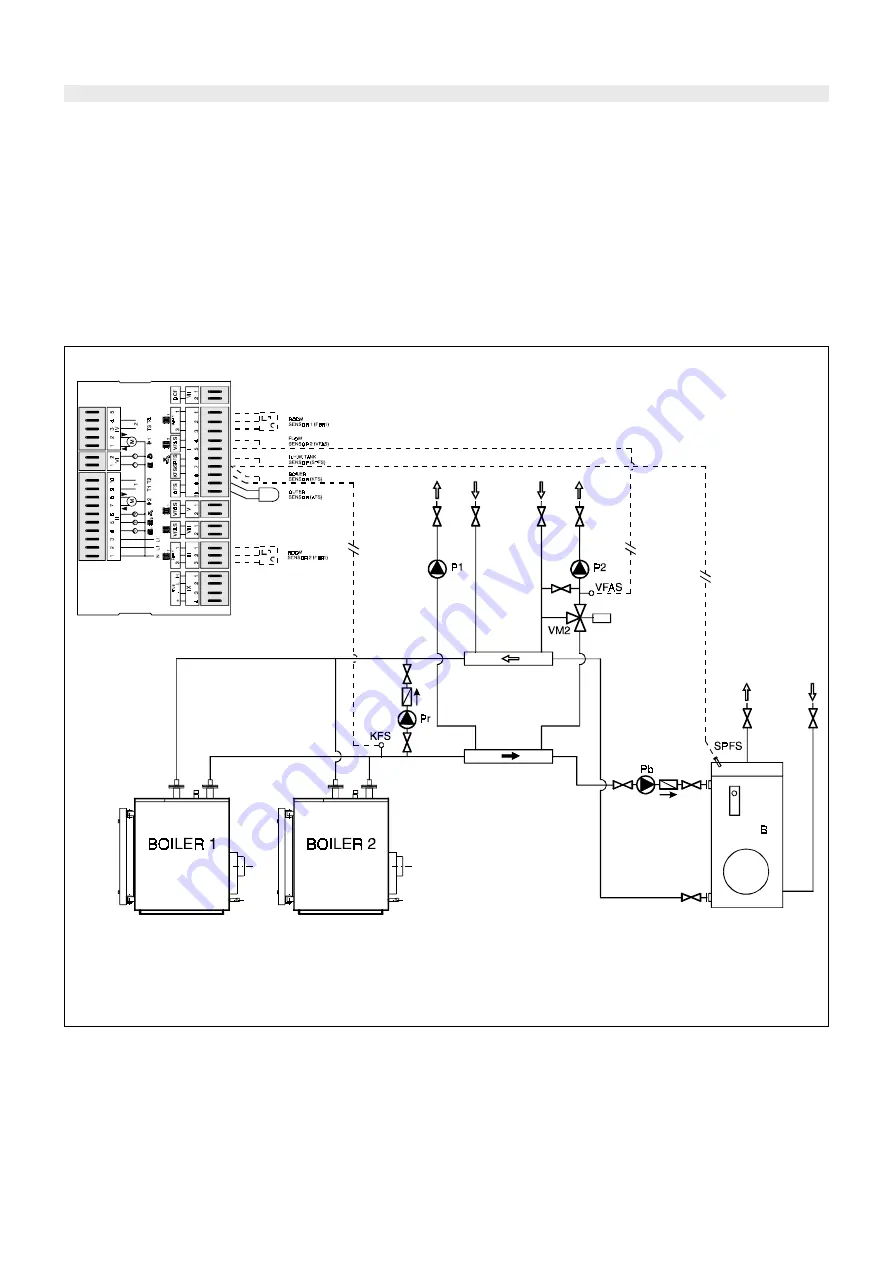

6.3 - ELECTRICAL AND HYDRAULIC CONNECTIONS OF C.H.

AND D.H.W. PRODUCTION CIRCUITS

In the fig. 35 the typical connection of the

boiler to C.H. system with two heating zones,

of which one is with motorized mixing valve.

Both, the heating zones are controled by an

outer compensator.

The electrical connections of the heating

pumps and the mixing valve motor must be

connected strictly according to the schemas

shown in the figs. 31 & 33.

The temperature sensors will be connected

according to the schema shown in fig. 34.

Remember that all the TRISECAL 3P boilers

are for forced circulation.

It is suggested to adopt a shunt pump "Pr" to

guarantee the circulation through the boiler in

any possible open condition of the mixing

valve (see fig. 35).

The shunt pump “Pr”, which will have a

throughput equal, at least, at 50% of the C.H.

pump and a manometric of of 1 m W.G., will

perform also an anticondensation function,

limiting the too cold returns into the boiler.

The hydraulic schema shown in fig. 35 are

principle schema; in case of different system

circuits, contact, please, our after sale service

dept., which will supply you with all the

necessary informations.

fig. 35

B Storage tank

C1/C2 Boilers

P1 C.H. pump for direct zone

P2 C.H. pump for mixed zone

As far as the outer compensator adjustment and programming are concerned, refer to the instruction manual supplied with outer

compensator. The parameters which can be modified by the user, according to his needs, are shown on the clause 4.5.

Pb Storage tank loading pump

Pr Shunt pump

VM2 Mixing valve

KFS Boiler temperature sensor

SPFS Storage tank temperature sensor

VFAS Flow temperature sensor