DUA plus 30 µ tank

2.7 -

MODIFICATION FOR

OTHER GASES

The boilers are manufactured for the type

of gas specifically required upon order.

Any subsequent conversion must be

performed by qualified technicians who will

use the kits supplied by

Unical

and perform

the conversion and required adjustments

for correct preparation of the boiler for use.

To convert the boiler from one type of gas

to another proceed as follows:

for conversion from natural gas to

LPG

- remove the main burner;

- disassemble the 15 injectors "1

11

11"of the

main burner and replace them with those

with a diameter corresponding to the new

type of gas (see table “INJECTORS -

PRESSURES”);

- reassemble the main burner;

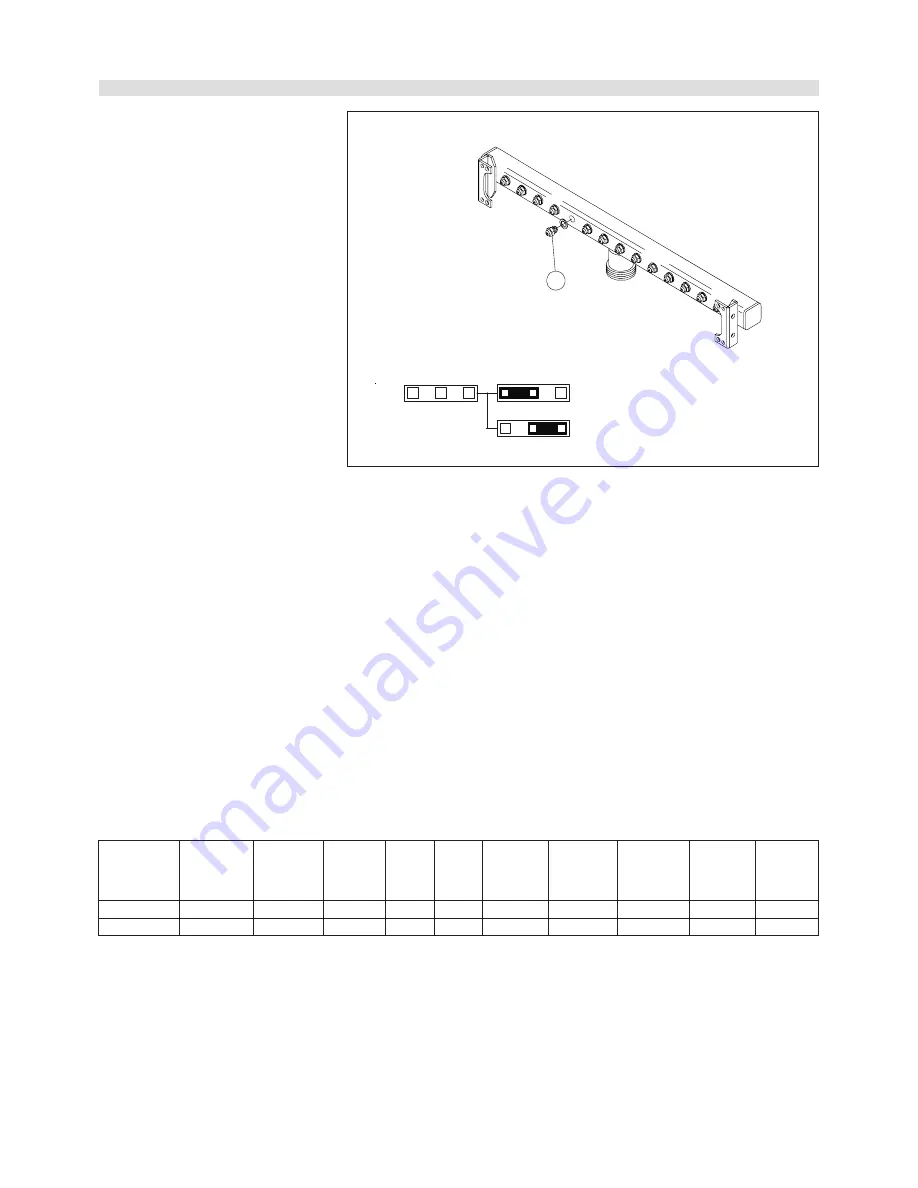

- position the jumper on the modulation PCB

in the panel board as shown in fig. 24

- remove plug

‘’A’’

(fig.21) on the gas valve

and fully tighten max pressure adjustment

screws

‘’C"

- check the pressure value upstream the

gas valve (see table “INJECTORS -

PRESSURES”) and adjust the min. pressure

of the burner as shown in section

" ADJUSTING THE BURNER”, by screwing

the nut "B" to increase or unloosing the nut

"B" to decrease the burner pressure.

- check that the burner is functioning

properly;

-

check that there are no gas leaks.

- tighten and seal the plug

“A”

(fig.28) of

the modulating coil (fig. 21)

- when the conversion is completed, fill in

the label, supplied with the kit, with the

information required and stick it onto the

boiler alongside the data plate.

for conversion from LPG to natural

gas

- remove the main burner;

- disassemble the 15 injectors of the main

burner and replace them with those with a

diameter corresponding to the new type of

gas (see “INJECTORS - PRESSURES”);

- reassemble the main burner;

- get access to the modulating PCB inside

the panel board and position the jumper

shown in thefig. 24;

- remove plug ‘

’A’’

(fig.21) from the gas

valve modulating coil and adjust the

maximum and minimum output s described

in paragraph 2.6 (A

A

A

A

A and B

B

B

B

B)

- check that the burner is functioning

properly;

-

check that there are no gas leaks.

- tighten the screw

“A”

of the plug of the

gas governor (fig.21);

- when the conversion is completed, fill in

label, supplied with the kit, with the

information required and stick it onto the

boiler alongside the data plate.

fig. 24

NOZZLES - DIAPHRAGMS - PRESSURES - GAS FLOW RATES

Gas type

Nominal

Output

(kW)

Nominal

Input

(kW)

Supply

Pressure

(mbar)

No. of

Nozzles

Ø of

Diaphr.

(mm)

Min

Burner

Pressure

(mbar)

Max

Burner

Pressure

(mbar)

Min

Gas Flow

rate

Max

Gas Flow

rate

Gaz H

(G20)

Gaz P

(G31)

13,9 - 29,95

13,9 - 29,95

15,5 - 32,2

15,5 - 32,2

20

37

15

15

Ø of

nozzle

(mm)

1,25

0,78

NO

NO

2,8

7,6

13,7

32,3

1,64 m³/h

1,20 kg/h

3,40 m³/h

2,50 kg/h

1

NAT

GPL

JP4

POSITIONING OF THE JUMPER

The pressures at the burner indicated in the following table must be checked after the boiler has been operating for 3

minutes.