UNIBLOC-PD Operation & Service Manual: PD501-576 9

QUICK CHECK LIST

A. Are pump and motor alignment within proper tolerances?

B. Do motor and pump gearboxes have adequate amounts of oil?

C. Has the piping to the pump been installed correctly?

D. Has the system and all pipes been flushed and cleaned of all debris including weld slag and particles resulting from polishing

and grinding?

2.1 Pump Head

Remove the front cover and make sure that no particles are trapped inside the rotor housing. Check that the rotor bolts have been

securely tightened, if design provides such an option. If possible, make sure pump turns freely. Put back cover, making sure o-ring

remains in place, and securely tighten the four front cover nuts.

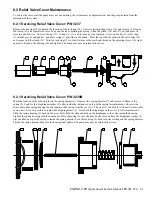

2.2 Direction of Flow

The pump is designed to operate in both directions without modifications. Make sure that the proper direction of rotation applies.

PRODUCT

FLOW

PRODUCT

FLOW

PRODUCT

FLOW

PRODUCT

FLOW

2.0 Before Start-Up

Summary of Contents for UNIBLOC-PD 501

Page 26: ...26 UNIBLOC PD Operation Service Manual PD501 576 8 0 Pump Dimensions UNIBLOC PUMP ...

Page 27: ...UNIBLOC PD Operation Service Manual PD501 576 27 UNIBLOC PUMP ...

Page 28: ...28 UNIBLOC PD Operation Service Manual PD501 576 UNIBLOC PUMP ...

Page 30: ...30 UNIBLOC PD Operation Service Manual PD501 576 UNIBLOC PUMP 9 0 Parts Lists ...

Page 31: ...UNIBLOC PD Operation Service Manual PD501 576 31 UNIBLOC PUMP ...

Page 33: ...UNIBLOC PD Operation Service Manual PD501 576 33 3 ...

Page 34: ......

Page 35: ......