data is unlocked, the tester returns to testing mode, and the symbol “

HOLD

” disappears. The tester

can store maximum 3000 groups of data.

7. Data Viewing/Deletion

Press “

ڼ

” to view data and display the stored data of Group No. 0001. Press “

ۆ

” and “

ڼ

” to move

the cursor, press “

MEM

” to confirm. The tester is designed with fast viewing mode (+1, -1, +10, -

10), press “

MEM

” once to view data by increment/decrement. Move the cursor to “+10, -10” and

hold down “

MEM

” to view data by increment/decrement at 100.

To exit data viewing mode and return to testing mode, please move the cursor to “Return” and then

press “MEM”.

8. Data Uploading

Connect the tester with computer via USB cable, turn on the clamp sensor, then operate the monitor

software. If the software displays open serial port and successful connection, the stored data can

be read, uploaded, and saved.

The monitor software can indicate maximum, minimum and average values, and have multiple

functions including dynamic display, real-time monitoring, alarming threshold setting, alarming

indication, data viewing/saving/printing, etc.

VII.

Battery Replacement

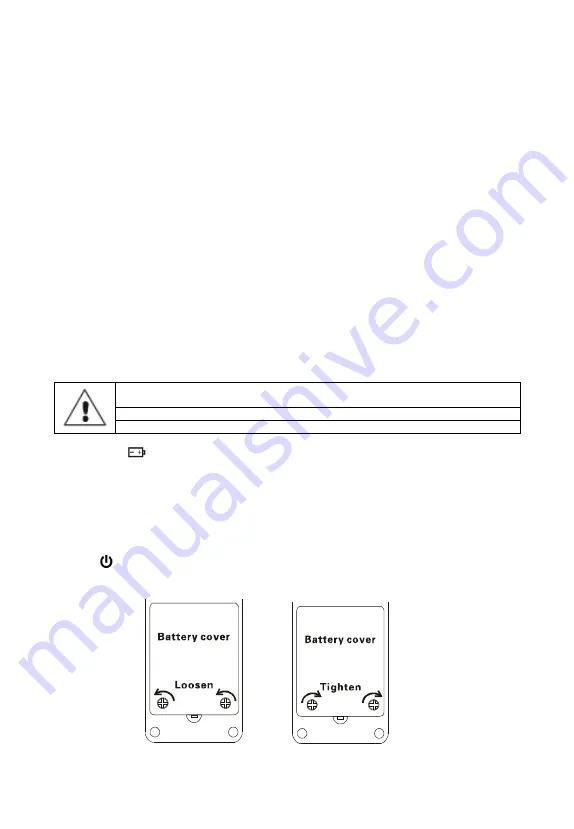

It is forbidden to test without battery cover set in place, otherwise it may pose

risk.

Pay attention to the battery polarity, otherwise it may cause product damage.

Do not apply new battery with used one.

1. The symbol “

” flashes if the battery voltage of primary clamp sensor is lower than 4.8V. If the

battery voltage of the tester is lower than 4.8V, the tester shows the low battery symbol to indicate

insufficient battery power, please replace the battery.

2. Power off the product, loosen the screws at the battery cover, open the battery cover, replace

with new batteries (pay special attention to the battery polarity), rejoin the battery cover, then tighten

the screws.

3. Press “

” to check if the product can be powered on normally. If the product cannot be powered

on, please repeat Step 2.

10